About the Class

In his global class, Neill expanded on the content of the local class, which introduced us to the Trotec 400 laser cutter and the Roland CAMM vinyl cutter. This included preparation of files for the two machines, pre-print routines and mechanical aspects, such as safety measures and material considerations.

Building a lighting edge sign

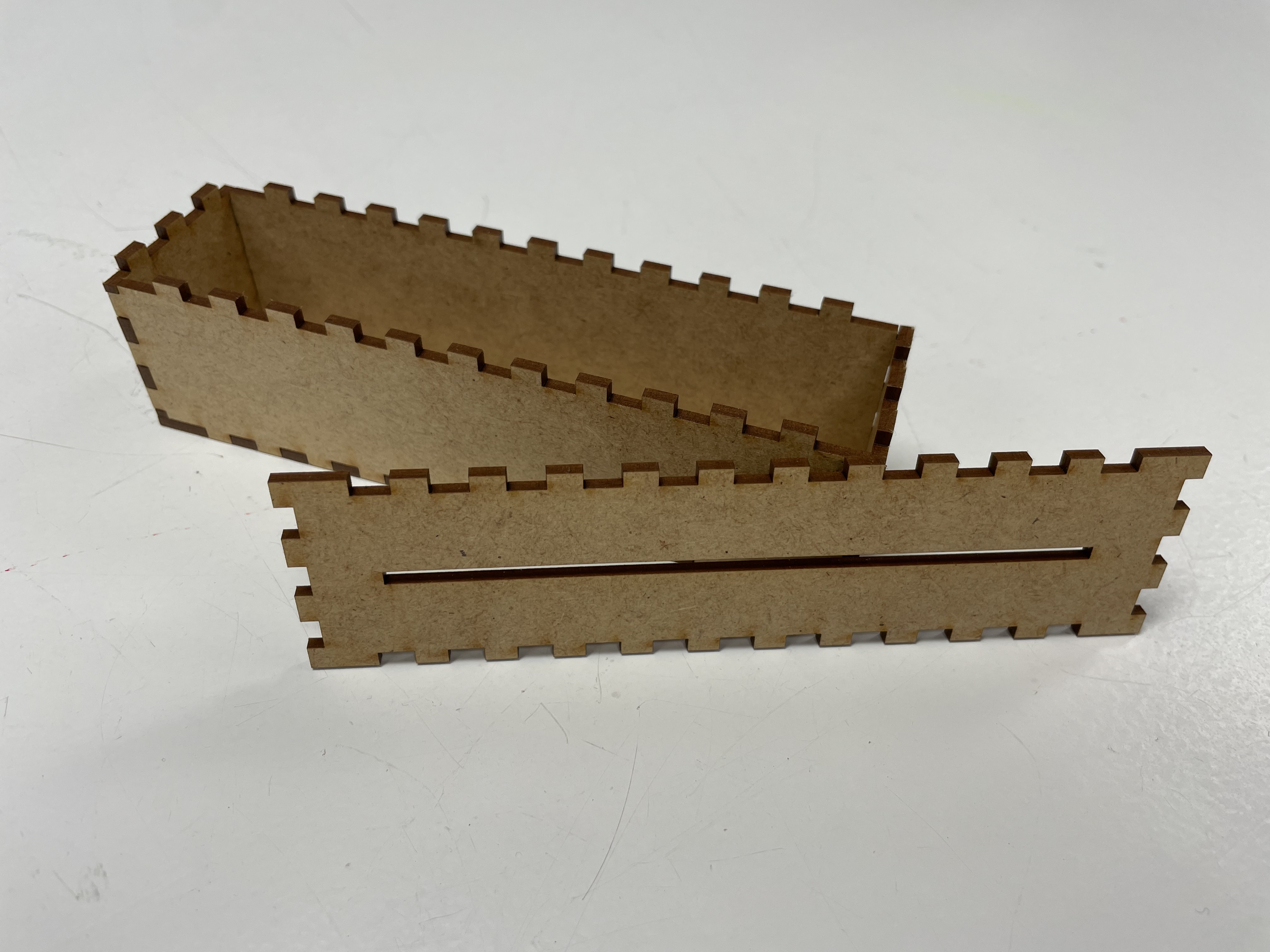

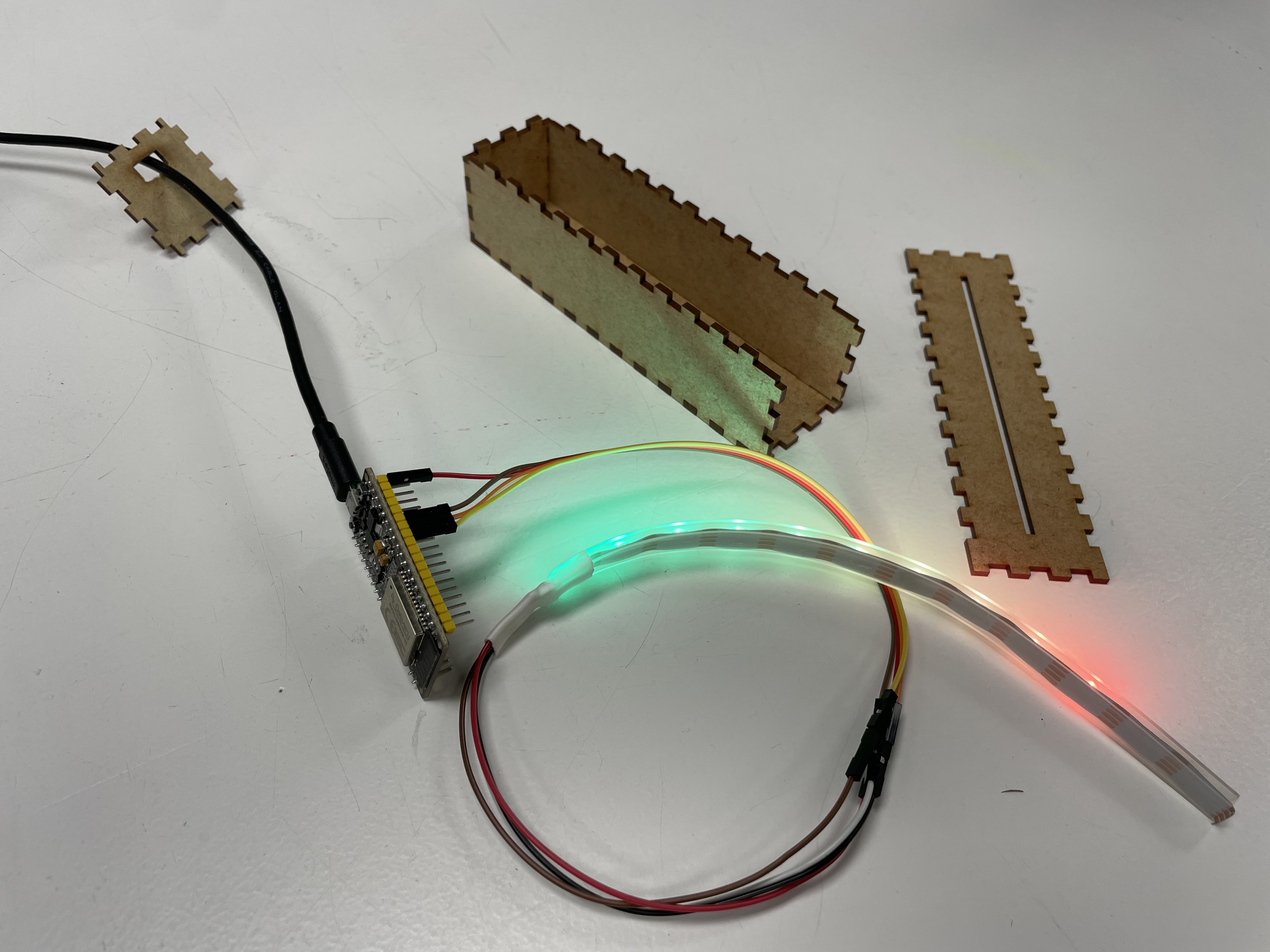

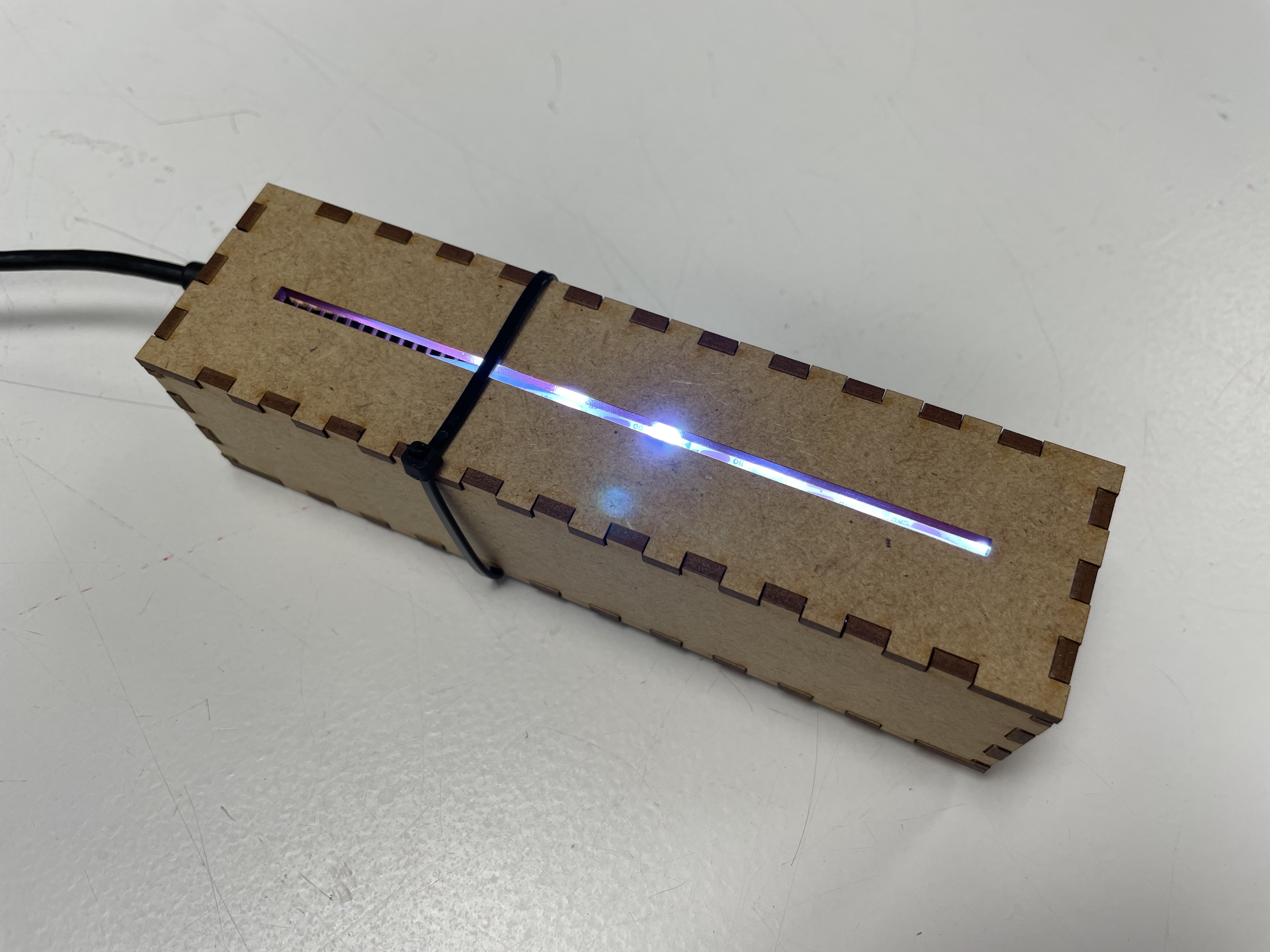

For my personal homework project, I decided to build a glowing edge light sign. It features a box, housing a LED strip and power supply, together with an engraved sheet of acrylic. By lighting the acrylic sheet from below, the engraved motive on the acrylic plate appears to be glowing. Using the Trotec 400 laser cutter, I manufactured the press-fit parametric box from 2,5mm MDF plates. As the time slots were heavily compressed when using the laser cutter, the acrylic sign was not manufactured on that day. Instead, I cut the acrylic sign in the subsequent week. For time reasons, I omitted the Grasshopper-generated background design on the sign.

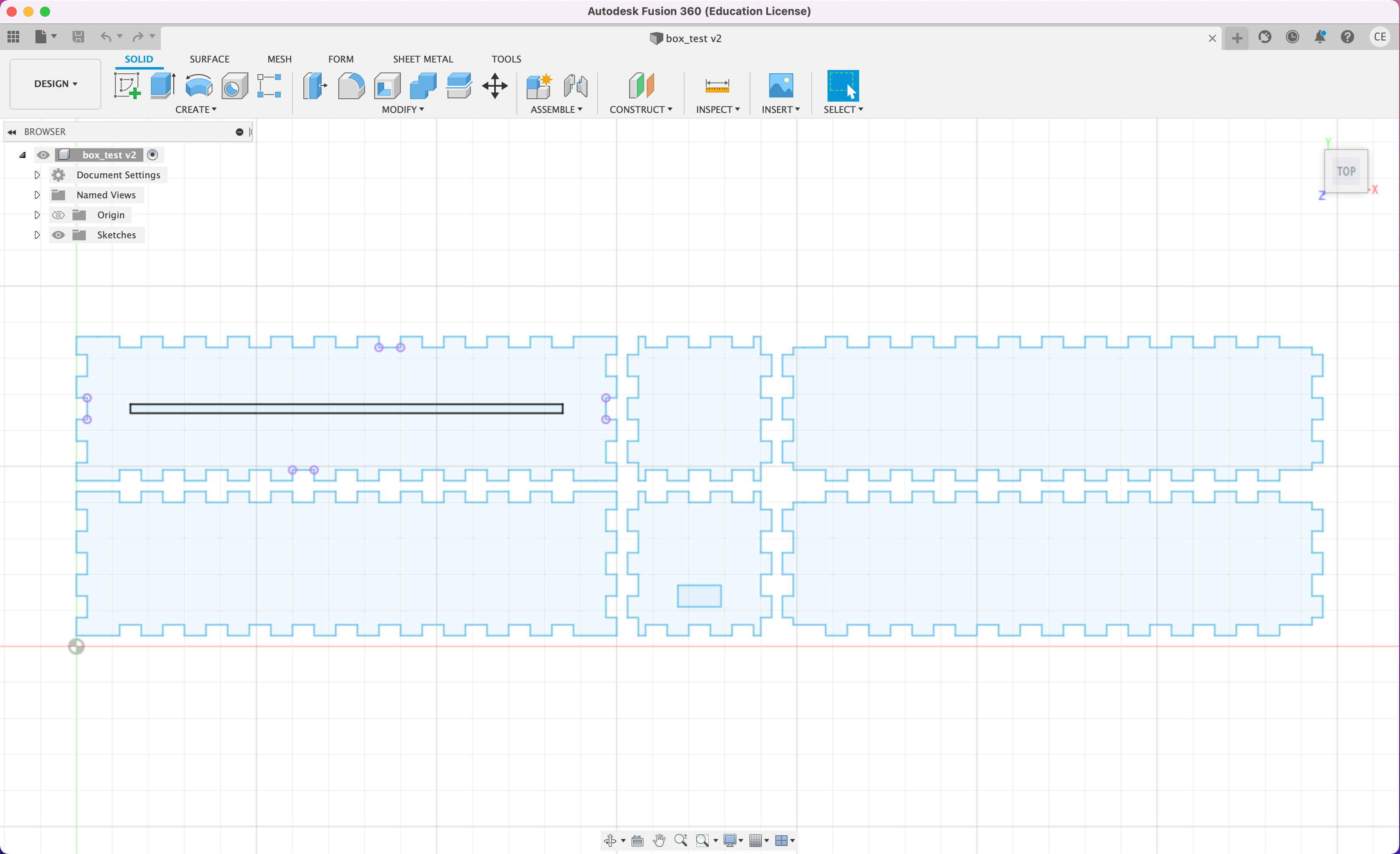

Parametric design file in Fusion 360.

Building steps of assembling the laser-cut pieces, integrating ESP32, programming LED strip.

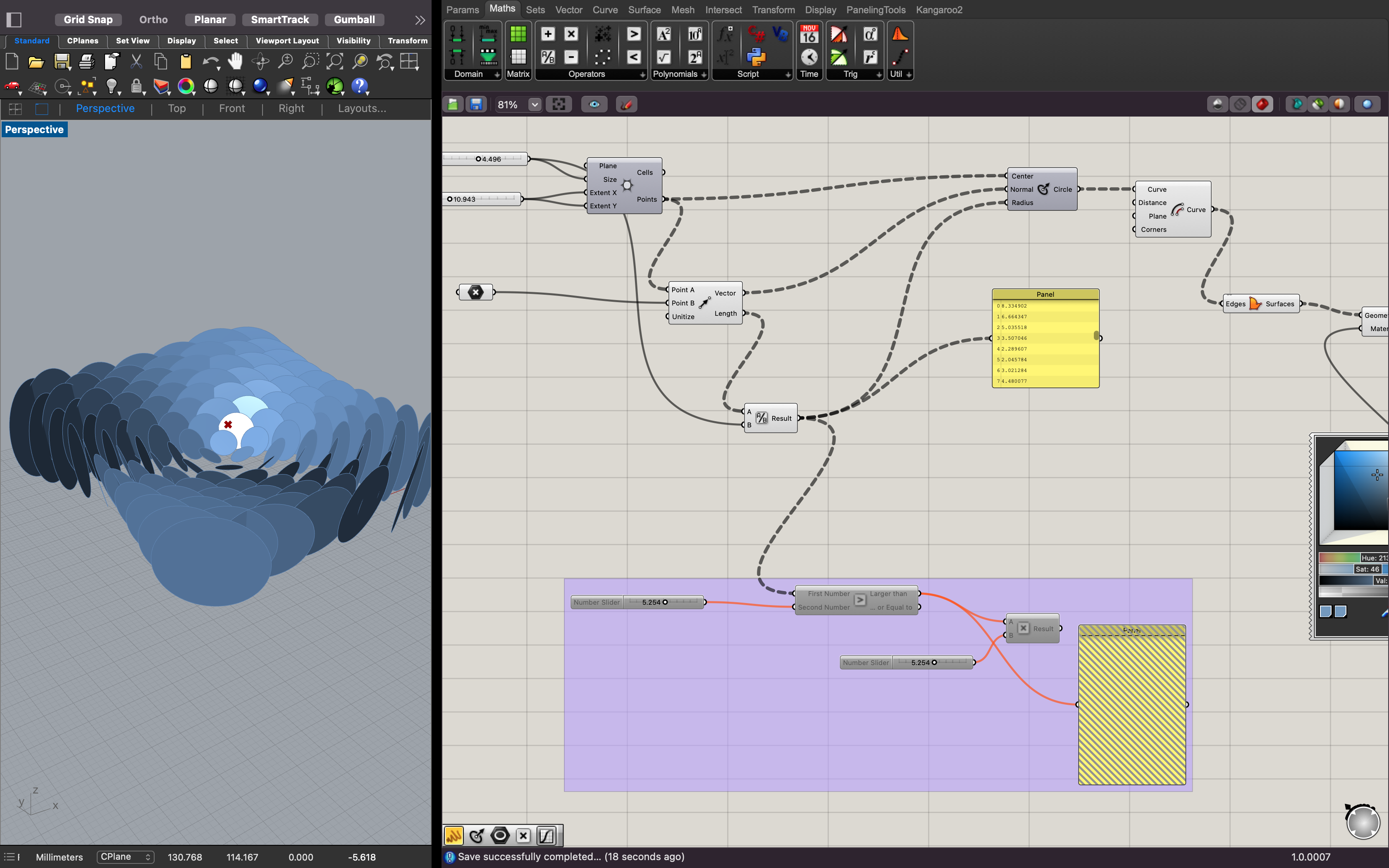

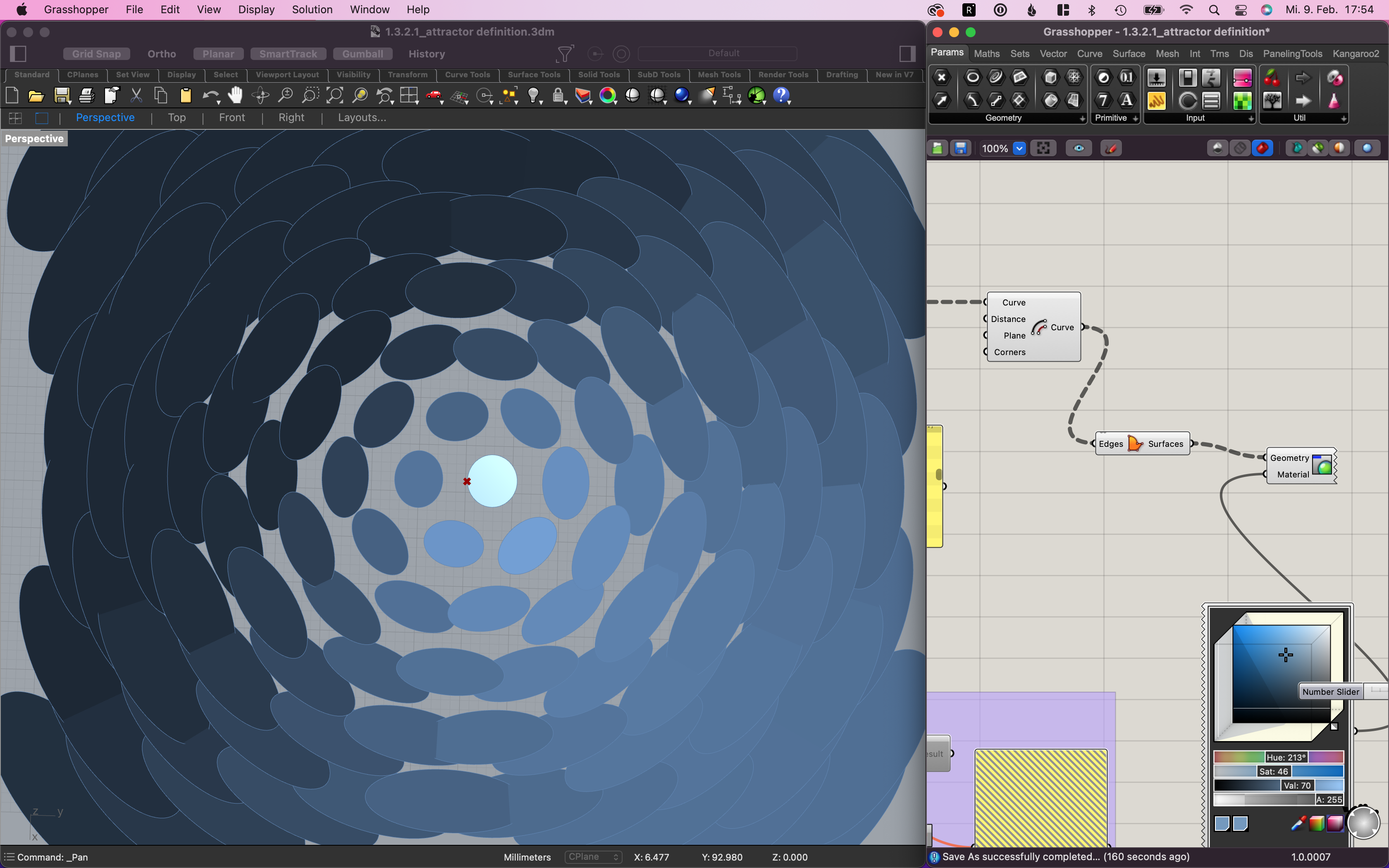

Experimenting with Grasshopper to produce an organic generative design.

Finding a perspective to export to SVG.

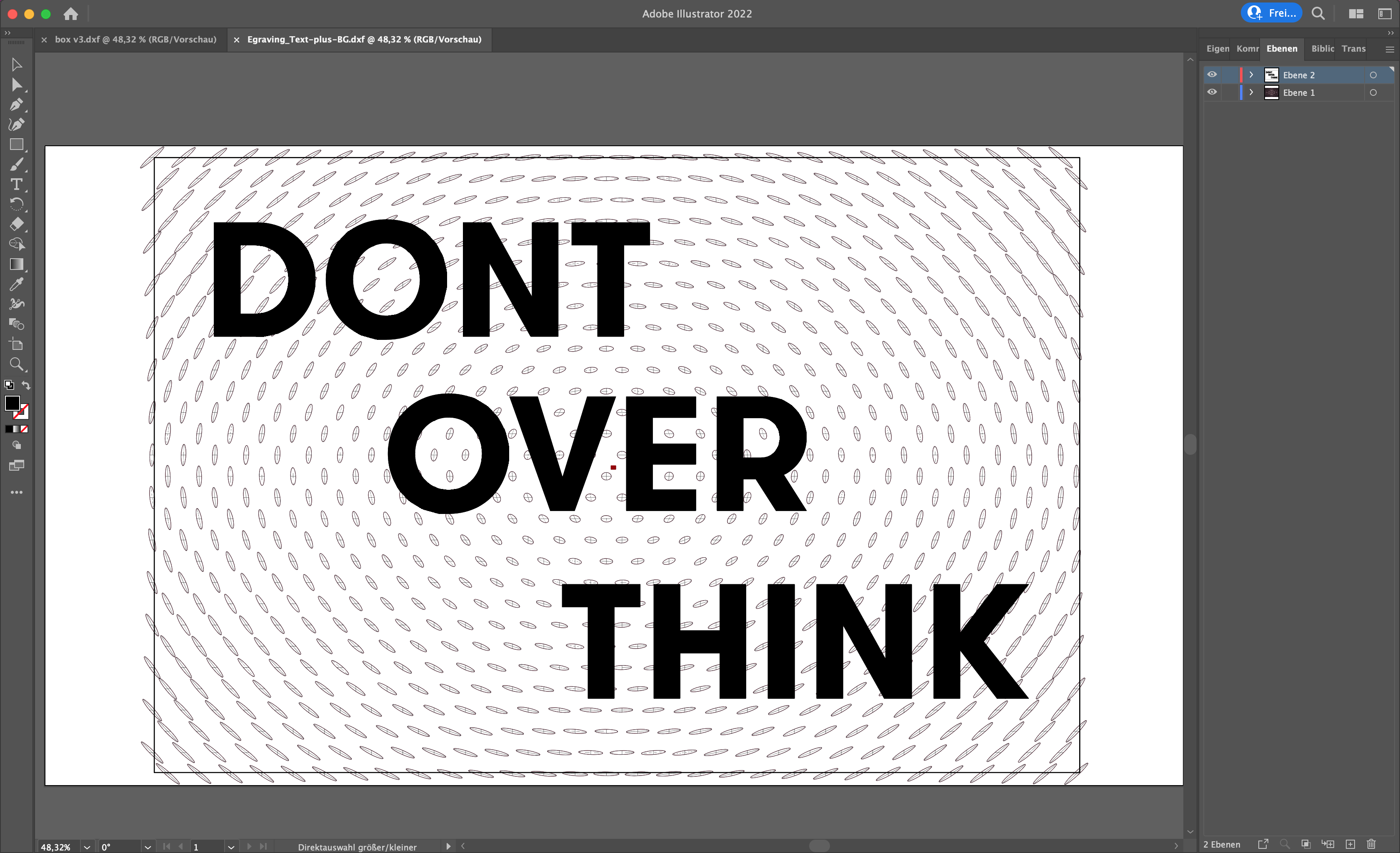

Designing the glowing sign in Illustrator to be engraved in acrylic.

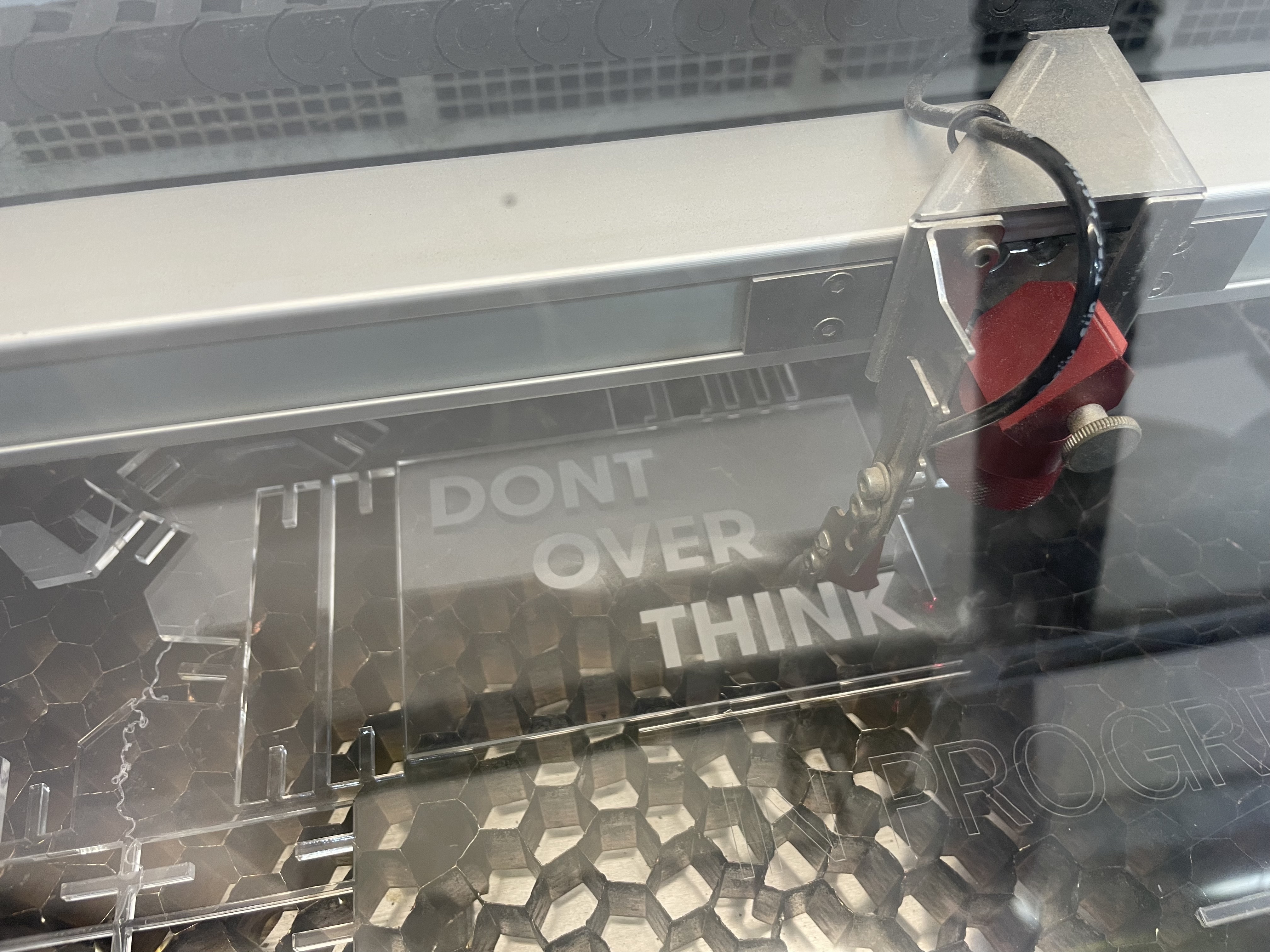

Engraving the acrylic plate in the small Trotec 100.

The final assembled light edge sign.

Further Links

tools

knife

Roland

Zund

Othercutter

ultrasonic

print and cut

Roland

laser

Epilog

Universal

Trotec

GCC

Full Spectrum

Lasersaur

3D FabLight

Oxford

PHAROS

plasma

Forest Scientific

Torchmate

waterjet

OMAX

Flow

WAZER

hot wire

FROGWire

Hotwire

MTM

wire EDM

Sodick

MTM

CAD

Inkscape

extensions

video

Rhino

Grasshopper

video

Blender

Sverchok

geometry nodes

FreeCAD

Sketcher

LCInterlocking

video

Fusion 360 Slicer

SolidWorks

xDesign

Onshape

Kiri:Moto

Cuttle

Kyub

Pepakura

VisiCut

flatfab

ExactFlat

CAM

printer drivers

Inkcut

Deepnest

mods

community

project

video

vinylcutter

applications

signs

thermal transfer

pop-up cards, books

origami, kirigami

screen printing

sandblasting

flex, multi-layer circuits

wiring harnesses

antennas

materials

knives

vinyl

masking tape

transfer adhesive

copper

epoxy film

sandblast stencil

settings

force

speed

cut depth

temperature, humidity, ...

rollers, feeding

weeding

adhesion

lift vs shear

lasercutter

applications

marking, engraving

raster

vector

screen printing

halftone

holes

path

app

press-fit construction

joints.FCStd

joints.png

GIK

GIK.FCStd

video

types

clearance

stress concentration

parametric design

parameter testing

living hinges, flexures, mechanisms

MEMS

Light Amplification by Stimulated Emission of Radiation

state diagram

population inversion

gain medium

lasing threshold

output coupling

beam mode, profile, waist

diffraction limit

gain medium

lifetime

CO2 (10.6 μm)

fiber (1-2 μm)

InGaAsP (1-2 μm)

AlGaAs (600-900 nm)

Nd:YAG (1064, 532 nm)

Ti:sapphire (650-1100 nm)

excimer (100-300 nm)

cutting mechanisms

burning

melting

evaporation

ablation

passes

airflow

assist

exhaust

filter

kerf

safety

classes

venting

airflow

outgassing

cleaning optics

supervision

fires

materials

cardboard

Edge Crush Test (ECT) 44

orientation

wood

custom

PMMA/acrylic/plexiglass/perspex/lucite

glue

bend

fold

POM/delrin/acetal

fabric

pasta

PVC flame test

[polycarbonate]

[metal] CerMark gypsum

settings

focus

power

speed

rate

coordinate system, origin

vector, raster

assignment

group assignment:

characterize your lasercutter's focus, power, speed, rate,

kerf, joint clearance and types

individual assignment:

cut something on the vinylcutter

design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways,

and for extra credit include elements that aren't flat