About the Class

In both the local and global class we were introduced into the theoretical concept and process of PCB milling and soldering. This extended into a hands-on introduction of soldering top-mounted components on PCB boards and handling the Roland SRM-20 mill. More on the details below.

Learning how to solder

After a theoretical introduction, we were given the chance to practice soldering hands-on. For that, we had special text boards with varying practical difficulty throughout board. After the intro, I had the chance to solder a lot more as it turned out: By building a 4-track collaborative loop station in the Fab Academy challenge week, we needed some 30+ connections to be soldered. After a couple of hours, I became more confident and quicker with soldering.

Eduardo explaining the ways to correctly place and solder components on a milled PCB board.

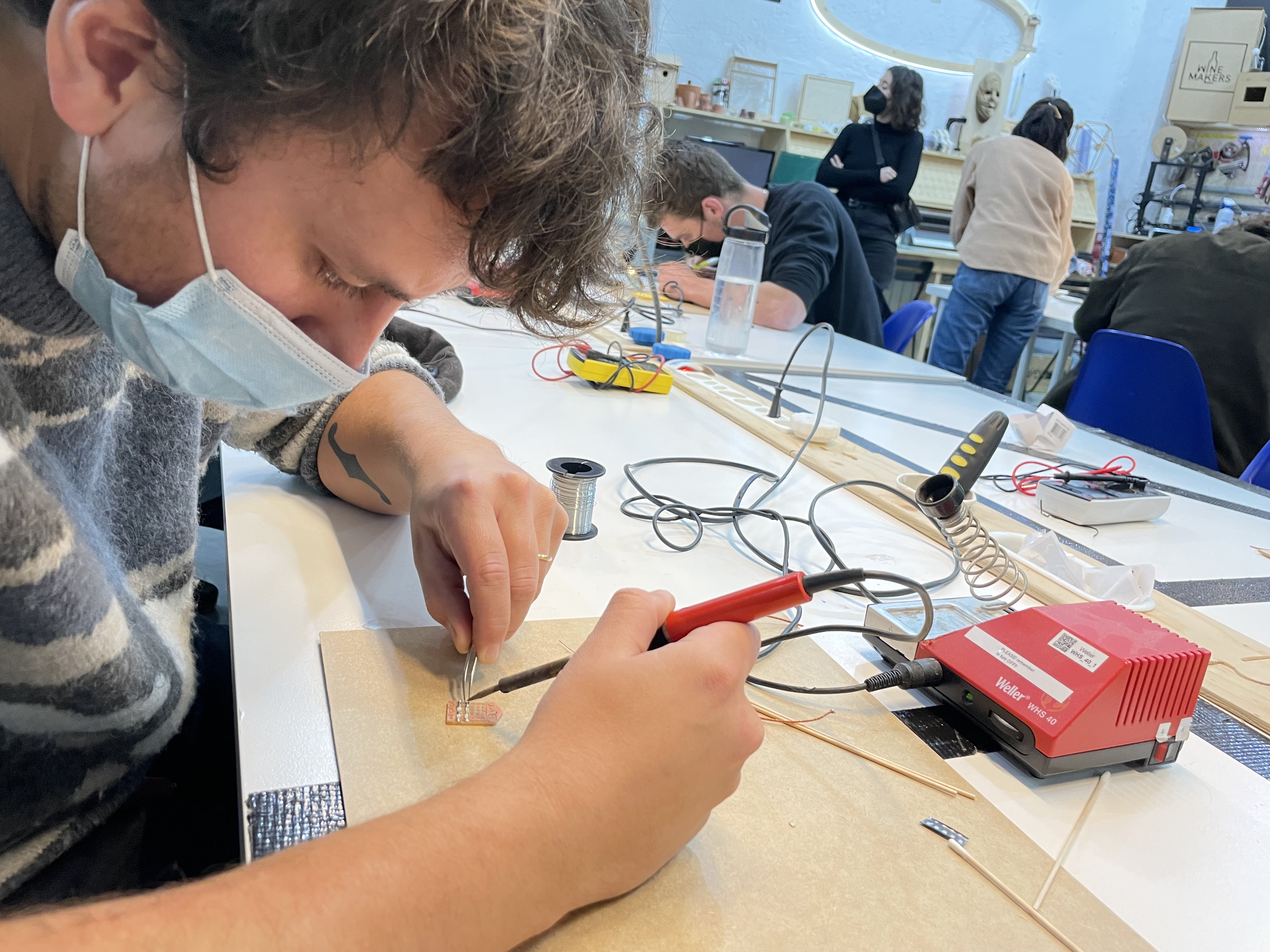

Joaquin practicing on the soldering test board.

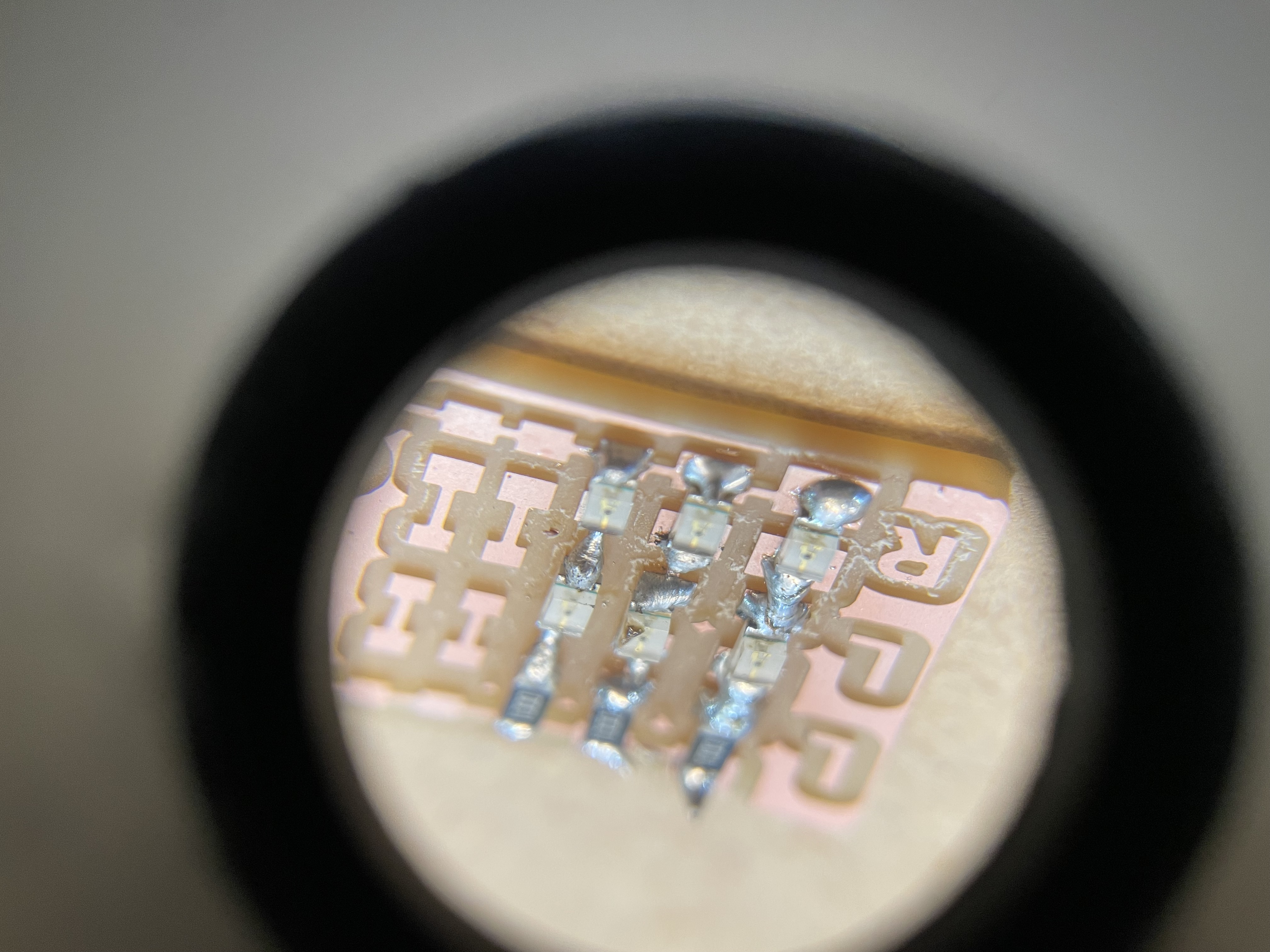

The result of practicing on the test board under a magnifying glass. From left to right, the quality of the solder connections can be seen (although still not incredibly great).

Honing my soldering skills during the first Fab Academy Challenge, soldering some 30+ connections.

PCB Design and Milling

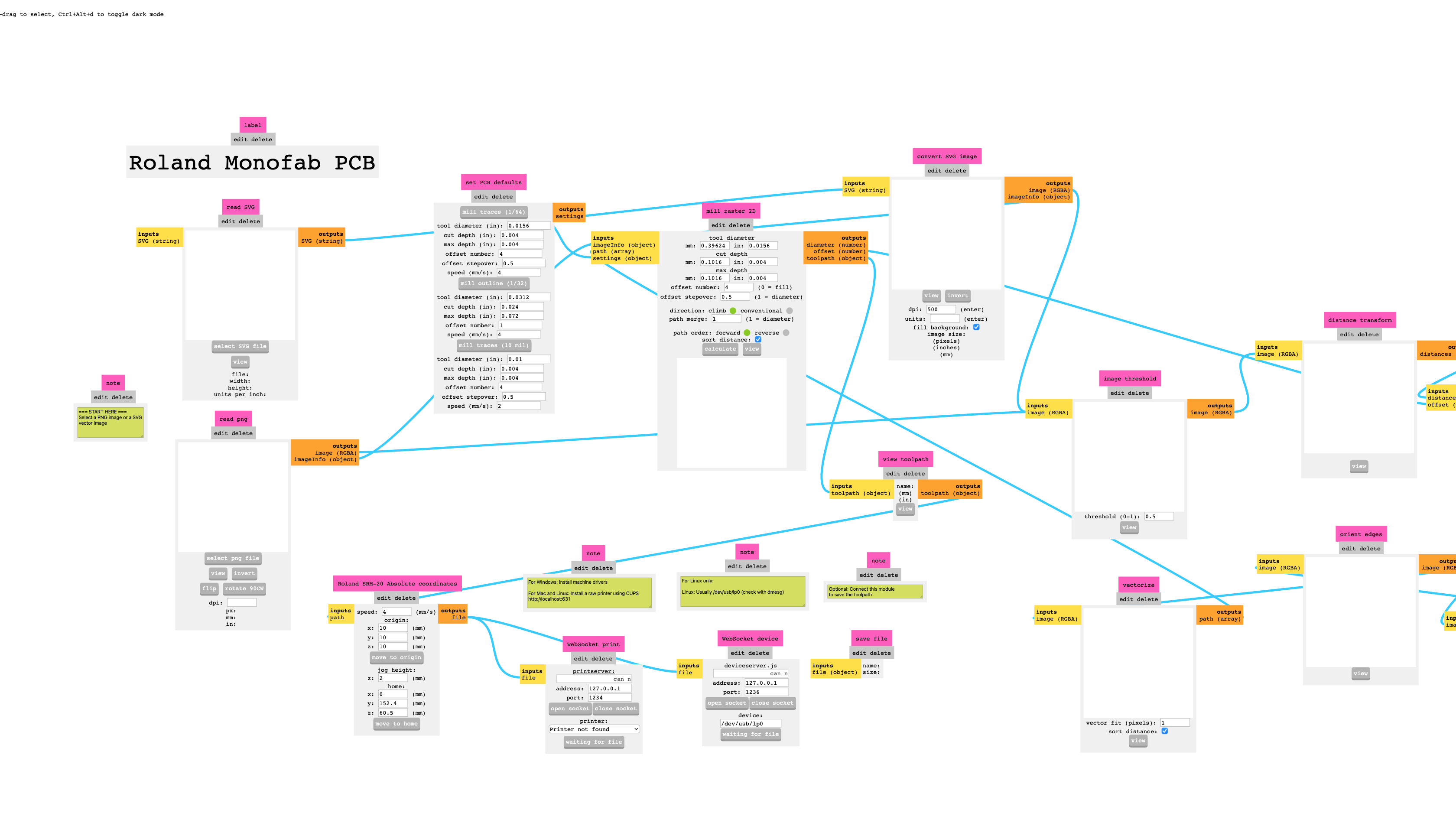

As for the custom PCB design and milling, one of the most important concepts is to understand how the drill moves across and through the copper layer on the substrate plate. To prepare high-resolution PNGs or SVGs for milling, we generate Gerber-files via Modsproject, which is a node-based formatting online tool developed and open-sourced by the MIT. In order to generate the files for the specific mills at the FabLab BCN, we need to open a new program (right click on canvas) and select Roland SRM-20 mill > PCB Absolute as settings.

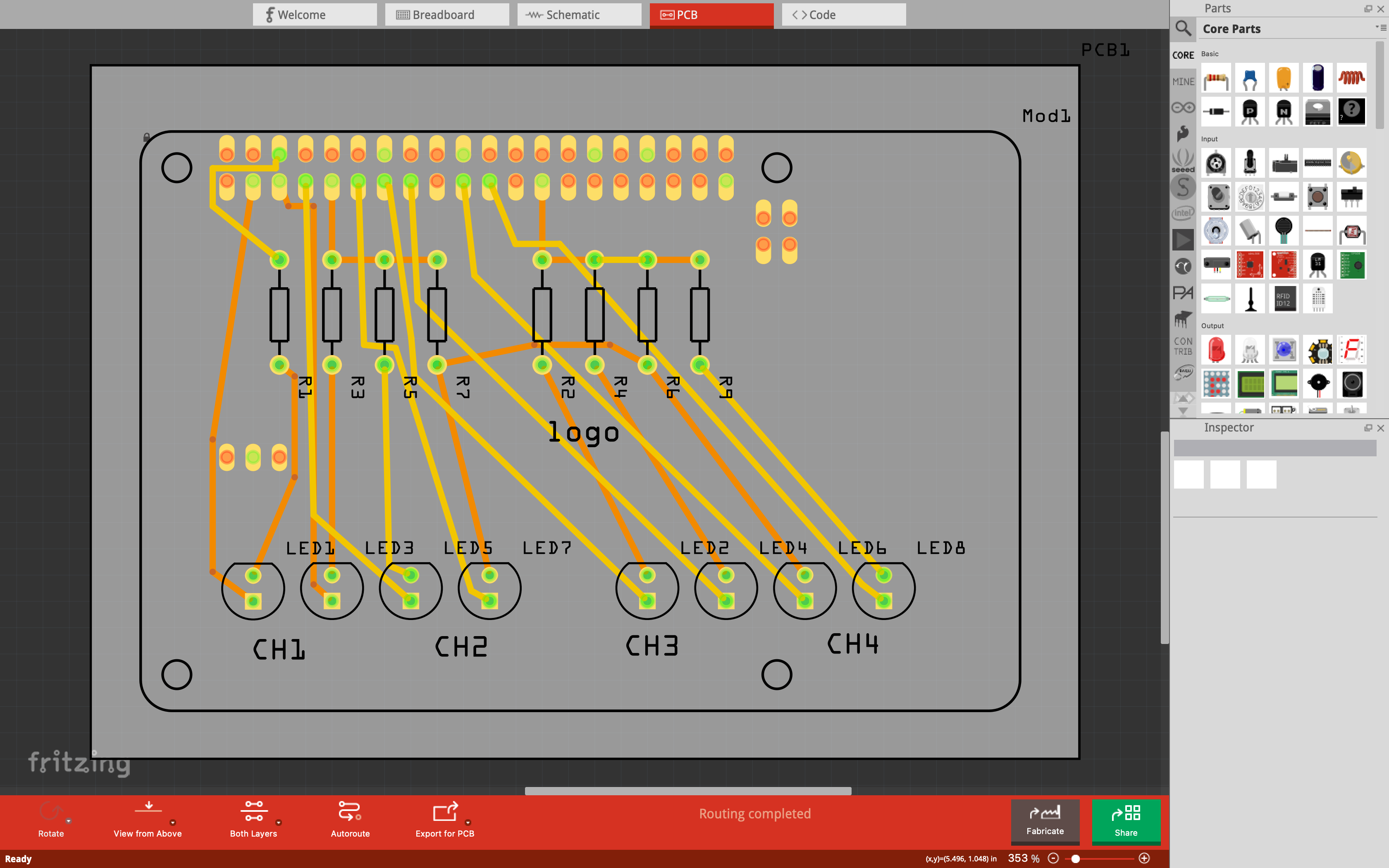

After soldering for a while during the first Fab Academy challenge week, the next step for the loop station should be to design a custom PCB board to reduce the amount of cables and the need for a breadboard. This will allow for a better layout of the components and a smaller physical footprint, since it can be implemented as a shield for the Raspberry Pi 4. I'm currently diving into Fritzing to learn how to design such a board exactly.

The modsproject nodes for processing a PCB design for the Roland SRM-20 mill.

Getting started designing a custom Raspberry Pi shield in Fritzing.

Further Links

PCB fabrication

etching

lithography, transfer

ferric/cupric chloride, ammonium/sodium persulfate

citric acid, peroxide

SDS

water consumption

waste

machining

machines

tools

0.010

1/64

1/32

V-bits

tapered bits

contouring bits

fixturing

underlay

orientation

zeroing

set-screws

lifetime

deburring

cleaning

climb vs conventional

vinyl cutter

flex

connections

encapsulation

milling

laser cutter

printing

conducting inks

plating

sewing

PCB materials

rigid

FR4 (epoxy glass)

FR1 (phenolic paper)

garolite

flex

Kapton, Pyralux

#1 epoxy film, #1126 copper tape

high-frequency

teflon

glass

copper

0.5 oz: 17.5 um

1.0 oz: 35 um

2.0 oz: 70 um

board houses

OSH Park, JLCPCB,

DKRed, Advanced, PCB:NG, Sierra, Screaming Circuits,

PCBWay

,

AQS, Gold Phoenix, 3PCB, Seeed,

Think & Tinker

PCB, kit, BOM

design rules

width/spacing (15, 5 mils)

layers

1, 1.5, 2, 2+, 4, N

mechanical, drill, solder mask, silk screen

vias

rivets, plated, blind, buried

components

through-hole

surface-mount

chip-scale

breadboards

assembly

solder

iron

station

fume extractor

ROHS

types

lead-free wire

paste

SDS

leaded wire

paste

SDS

low-temp wire

paste

eutectic

wetting

manual, drag, wave

cold solder joints

flux core, paste, pen

reflow

hot air, hot plate, oven, IR

magnifying

stuffing

component orientation

tacking down parts

bottom to top, inside to outside

fumes

washing

desoldering

braid

vacuum

hot air

gravity

cutting traces, adding jumpers

pick-and-place

encapsulation

CAM

formats

Gerber/RS-274X

png resolution

FlatCAM

cam.py → cad.py → kokompe → fab modules → mods

community edition

video

trace width

traces

interior

1/64"

0.010"

fiber laser

assignment

group assignment:

characterize the design rules for your in-house PCB production process

extra credit: send a PCB out to a board house

individual assignment:

make an in-circuit programmer that includes a microcontroller:

extra credit: customize the design

mill and stuff the PCB

test it to verify that it works

extra credit: try other PCB processesamet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare, eros dolor interdum nulla, ut commodo diam libero vitae erat. Aenean faucibus nibh et justo cursus id rutrum lorem imperdiet. Nunc ut sem vitae risus tristique posuere.