About the Class

In today's class we learned about the basics of CNC-ing: What materials can be milled in which scenario and with which machines. Multiple examples for 2D and 3D milling were given.

CNC-milling a biomaterial mold

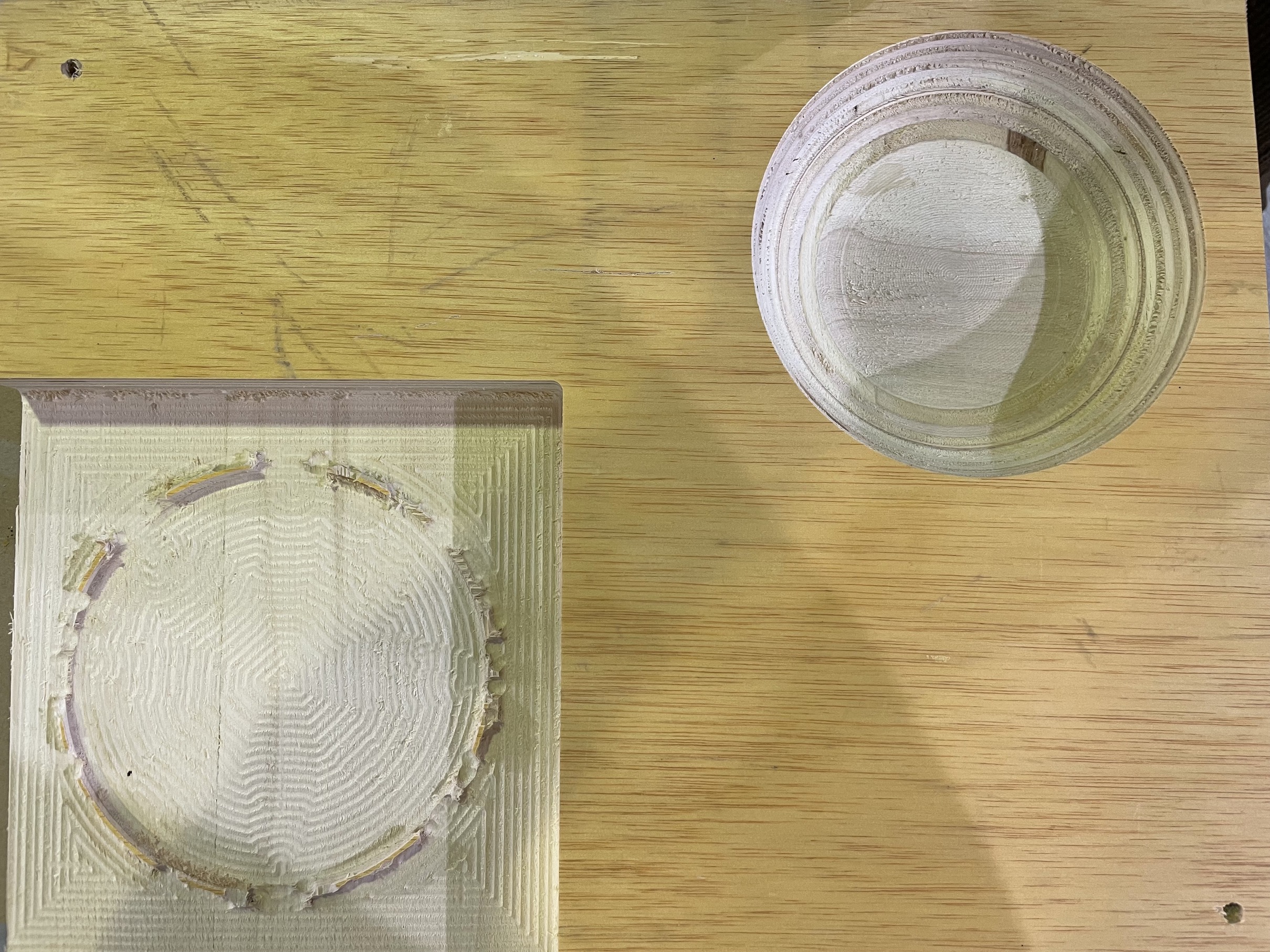

For the homework, George and me decided to mill a 3D mold to manufacture bowls from biomaterial. For this, we prepared a 3D file which was then checked by FabLab staff. Unfortunately the design didn't feature a watertight 3D volume but instead was an open shape. Therefore after perfectly milling our molds, the machine continued to drill into the finished positive and milled it down entirely. The result can be seen below. Let's just say it was a painful, but effective lesson on why to double check your 3D files before generating the g-code.

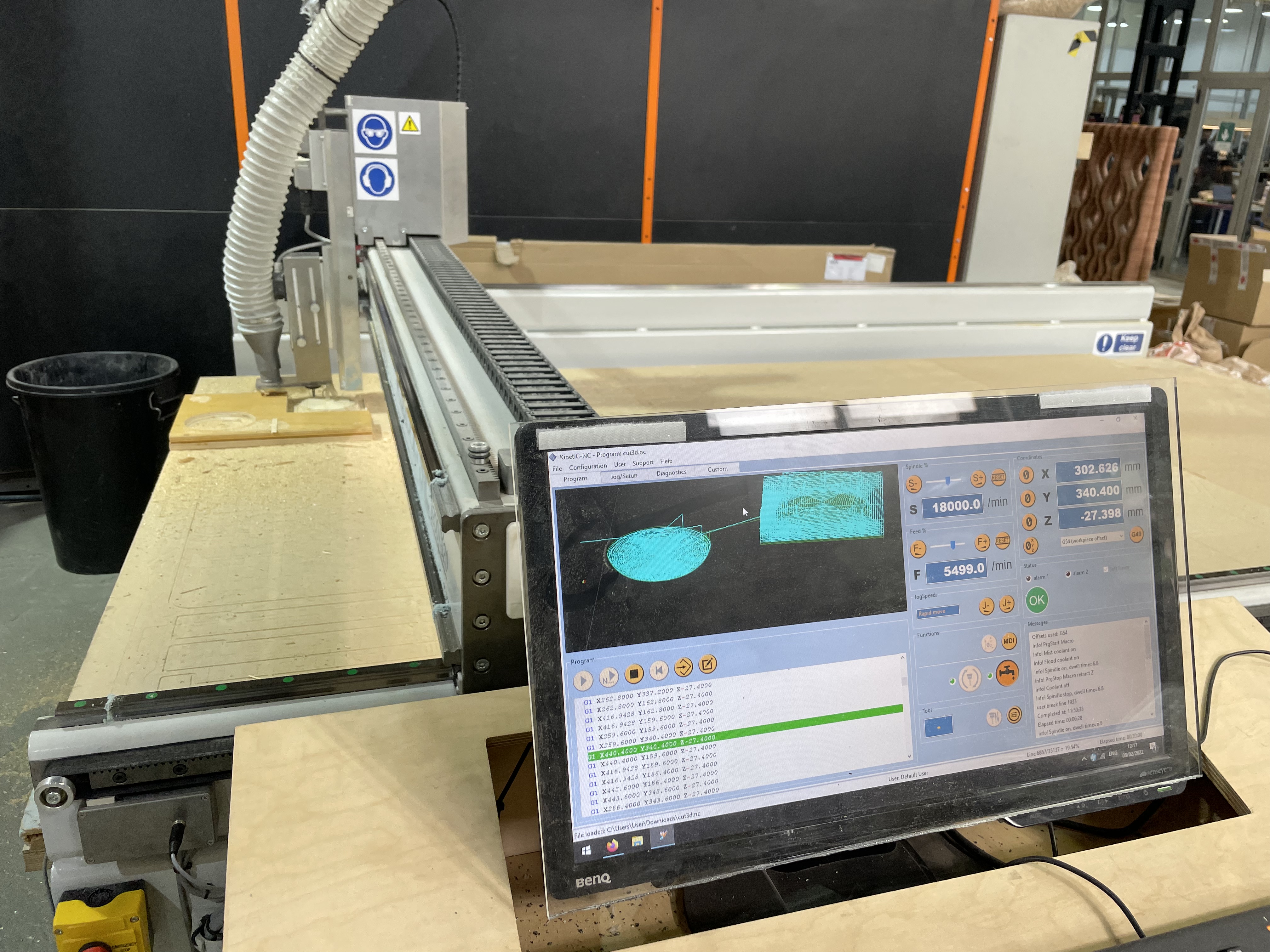

During the milling process using the Raptor CNC.

The finished piece. In the bottom left, the destroyed positive can be seen clearly.

Further Links

projects

Standing Desk, Opendesk, AtFab

Shelter 2.0, yourHOUSE, Wikihouse, FabHouse, Fab Lab House

10,000 Year Clock

machines

Shaper

Maslow

ShopBot

Onsrud

Tormach

Haas

Hurco

Zund

MTM

Fellesverkstedet

stock

cardboard

rigid foam insulation (gesso, heat gun)

veneer plywood

Medium Density Fiberboard (MDF)

Medium Density Overlay (MDO)

Oriented Strand Board (OSB), finishing, covering

Valchromat

HDPE

Lexan, polycarbonate

Garolite

Aluminum (Composite Panel)

vendors

McMaster-Carr

US Plastics

Admiral Metals

Home Depot

Boulter Plywood

Steritt Lumber

Beacon Sales

job shops

Proto Labs

Star Rapid

Yubo Precision

DSH

Cycle Start

Fast Forward Composites

Xometry

tooling

drills vs mills

router, V bits

flutes

coatings

center-cutting

up/down cut

flat/ball end

speeds and feeds

chip load: ~ 0.001-0.010"

feed rate (inches per minute) / (RPM x number of flutes)

cut depth: ~ tool diameter

step-over: ~ tool diameter/2

lubricants

abrasive machining, grinding

fixturing

vises

bar clamps

screws

nails

vacuum

wedges

weights

glue

tape

encapsulation

sacrificial layers, squaring

dust collection

flexures, living hinges, kerfing,

steam bending,

wacky wood

fasteners,

glues

joinery, reciprocal frame, tensegrity, Maxwell criterion

toolpaths

kerf, offset, runout

conventional, climb

rough/finish cuts

high-speed, dry, ramping, adaptive clearing, swarf, rest, trochoidal

one-sided, two-sided, registration

2, 2.5, 3, 4, 3+2, 5 axis

tool length compensation

cut depth, clearance, collisions

T-bones, dog-bones

tabs, onion skinning

nesting

lead-in, -out

test cuts, cutting air

simulation

prototyping

CAM

CAMotics

VCarvePro

FeatureCAM

Mastercam

HSMWorks

CAMWorks

Freecad Path

Solidworks CAM

Fusion 360

OpenBuilds

mods

community

outline

rough

finish

file formats

.rml

.sbp

.g

.ord

safety

training

splinters, cuts, burns, impacts, fires

tool breaking

glasses, shoes, clothes, hair, gloves

look, listen, smell

don't reach into a powered tool

emergency stop, assistance

personal state

welding

arc

MIG (metal inert gas)

TIG (tungsten inert gas)

spot

friction

ultrasonic

assignment

group assignment

do your lab's safety training

test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

individual assignment

make (design+mill+assemble) something big (~meter-scale)

extra credit: don't use fasteners or glue

extra credit: include curved surfaces