3D Printing Clay with a Modified Ender 3

For Joaquins project 'Sonic Ecologies' I helped with some of the steps necessary to 3D print with clay. The goal was to collect clay from Valldaura, as well as environmental audio recordings, to use both to transform them into physical 3D artifacts. By slowing down the recordings, folding the sound waves into a circle and then lofting two of them into a 3D volume allowed Joaquin to achieve an interesting 3D object that embodied the story of the material and its surroundings.

Printing the object with the original clay proved to be a challenge however. Due to the high degree of small particles, such as sand, which persisted in the material even after sieving, the substance was more brittle and fragile when compared to industrially processed pottery clay. Consequentially, most of the 3D volumes were printed with this material to guarantee a smooth printing process. Below some impressions of the process and the final outcome can be found.

Original clay collected from Valldaura. Notice the high percentage of small particles, such as sand, which made it challenging to find the right water to substance mix ration.

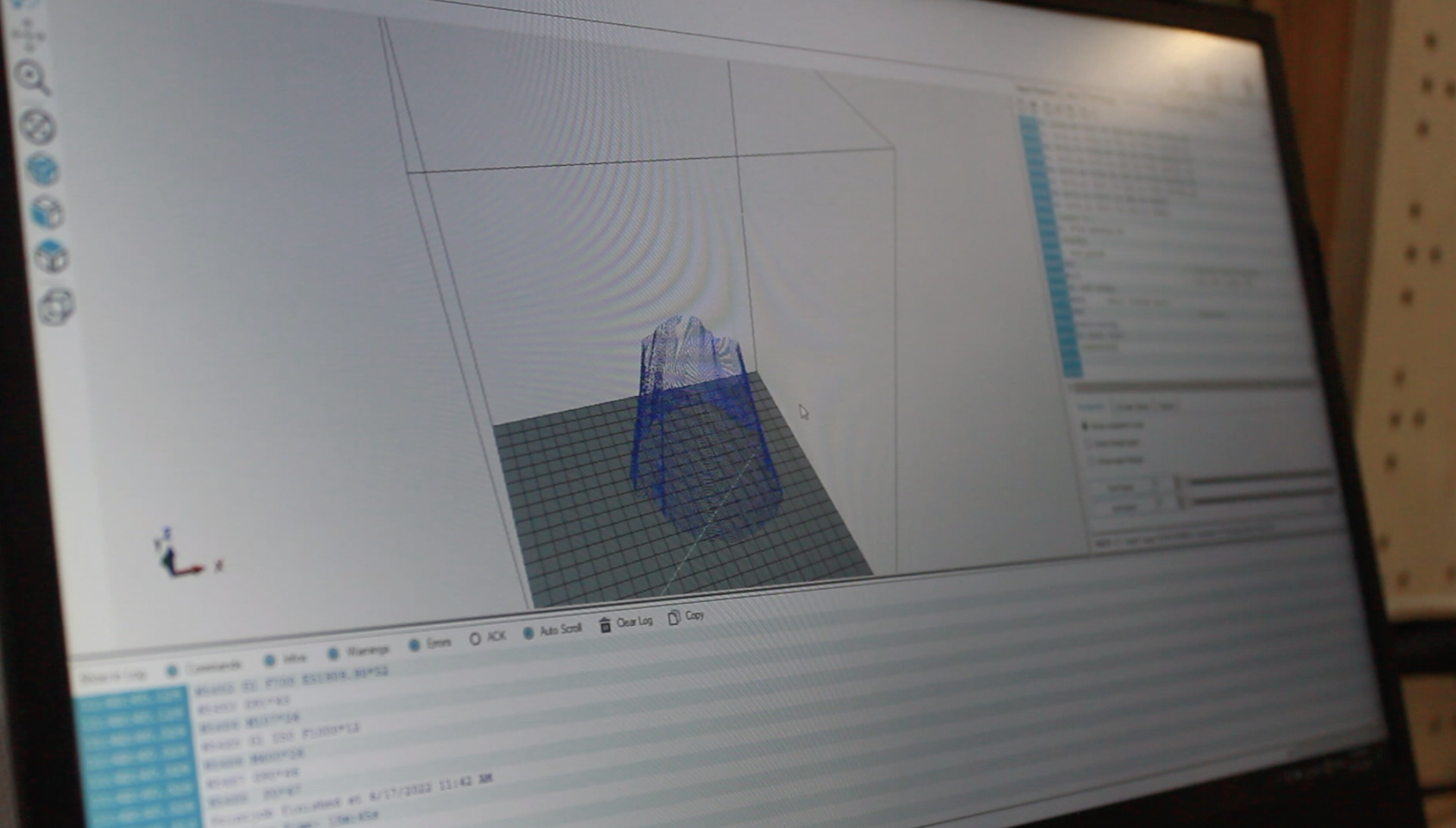

Lofting two slowed-down sound waves to generate the 3D volume.

Monitoring the pressure provided by a compressor going into the clay cartridge. This is necessary to feed a continuous stream of substance into the modified extruder of the Ender 3, where a spindle controls the final outflow of material.

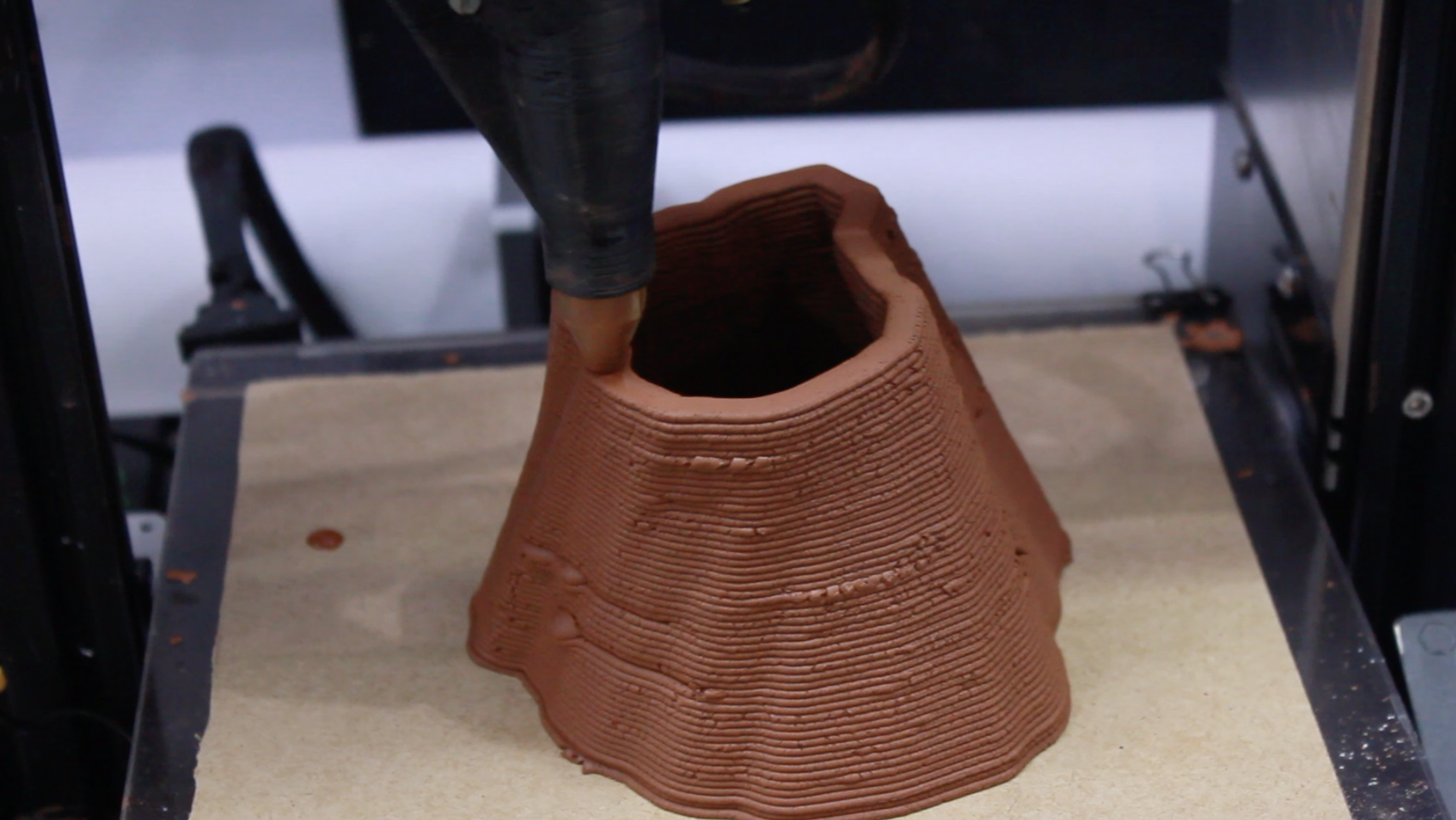

Here, the quality of the print can be seen close-up. This object was not printed with the Valldaura clay but with the standard industrial red clay typically used in pottery.

An object close to completion, while printing. Notice the increased print line width to achieve a more stable result.

Further Links

Wildcard Week

assignment

Design and produce something with a digital fabrication process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it. Possibilities include (but are not limited to):

machines

electrical discharge machining

5-axis machining

waterjet cutting

flatbed cutting

plasma cutting

laser metal cutting

laser micromachining

welding

molding and casting

vacuum forming

rotocasting

folding

mathematics

form and function

robotics

arms

construction

soft

actuation

pneumatic

inflatable

electronics

pick and place

programmable logic

embedded programming

machine learning

machine vision

food

printing

gastronomy

materials

synthesis

mechanical

rheological

biotechnology

DIYbio

iGEM

HTGAA

Bio Academy

textiles

fiber processes

knitting

embroidery

PEmbroider

Ink/Stitch

Fabricademy

composites