Fabricating an Arduino Uno Shield

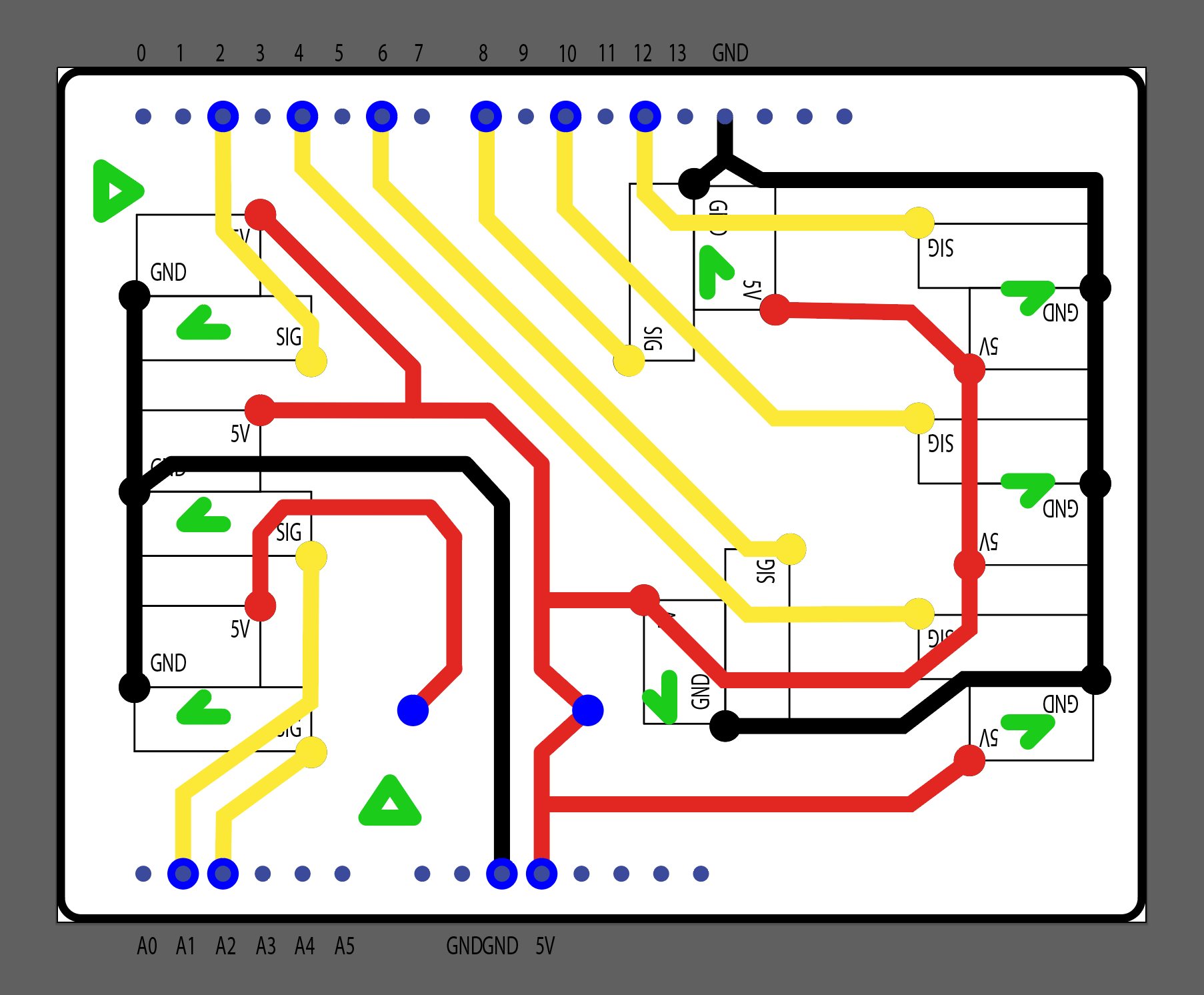

Designing the PCB

The function of the PCB was to multiply the 5V and GND pin outputs for the Arduino UNO Rev3 in the context of our Fab Challenge 4 (full documentation here and on Github). This was necessary to provide an apt amount of available headers for the 12+ control units that will be connected to that single Arduino. After working with Fritzing before in Week 6 (Electronics Design), I gave it another shot but was (again) disappointed by the UX and lack of control over some critical parameters, such as trace width. Then I switched to Illustrator, which is much more bare-bones (because it doesn't offer any kind of presets), but allows an unprecedented control over everything. It's important to note that this is also precisely the reason why it doesn't prevent you from making critical mistakes, such as defining a prohibitively narrow clearance for the 1/64" drill or just simply setting the wrong design ratio overall. Additionally, I designed the board in an inverted way for the female headers to be soldered from the bottom (more on that below), so the design was actually flipped along its horizontal axis. I assume this is could have been another error-prone step in the design process.

Find the design files here

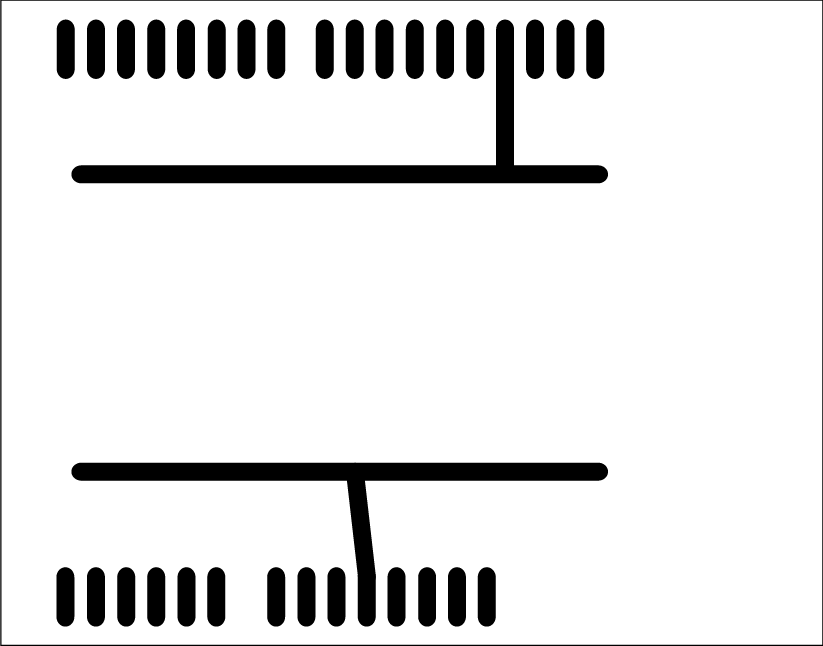

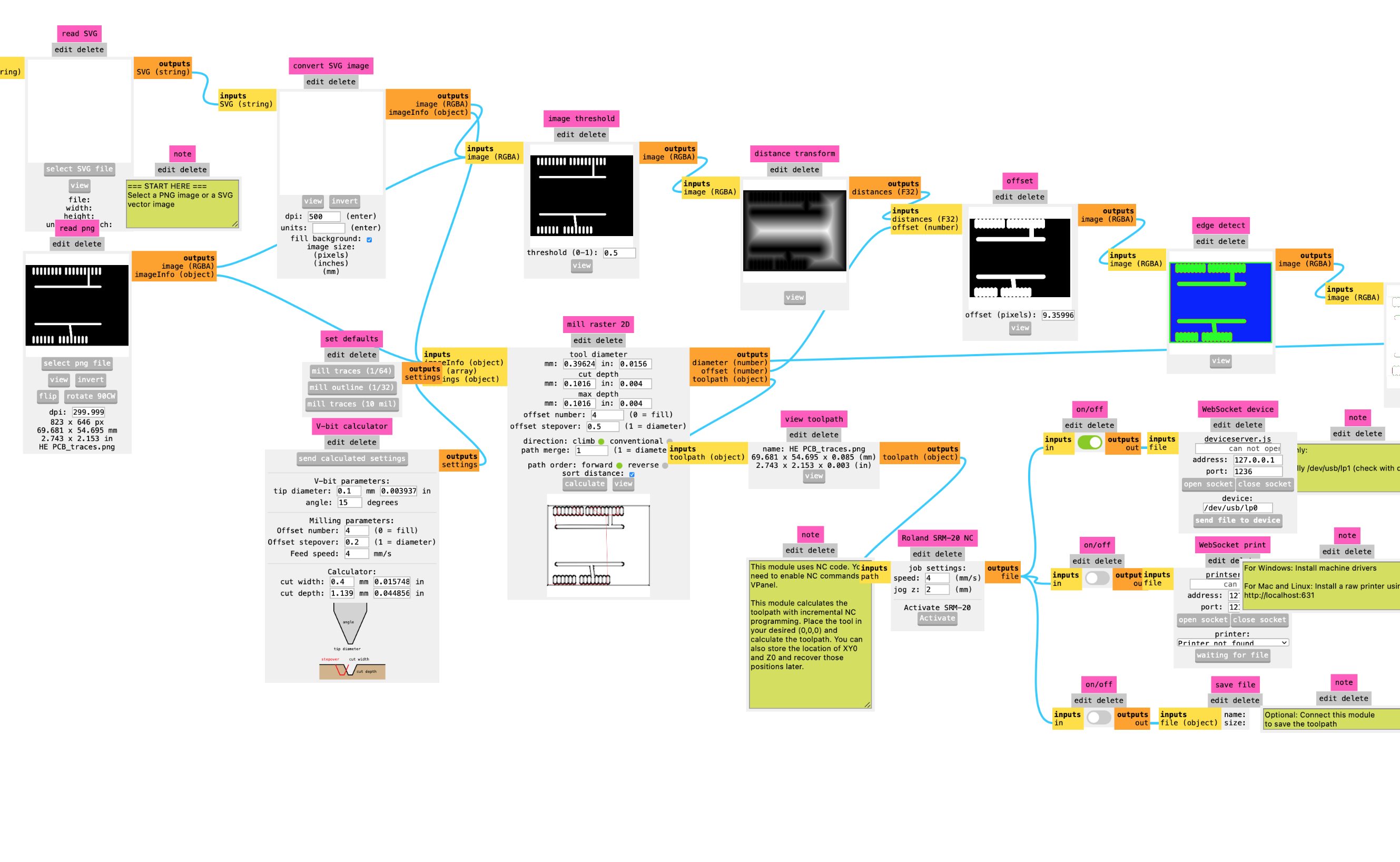

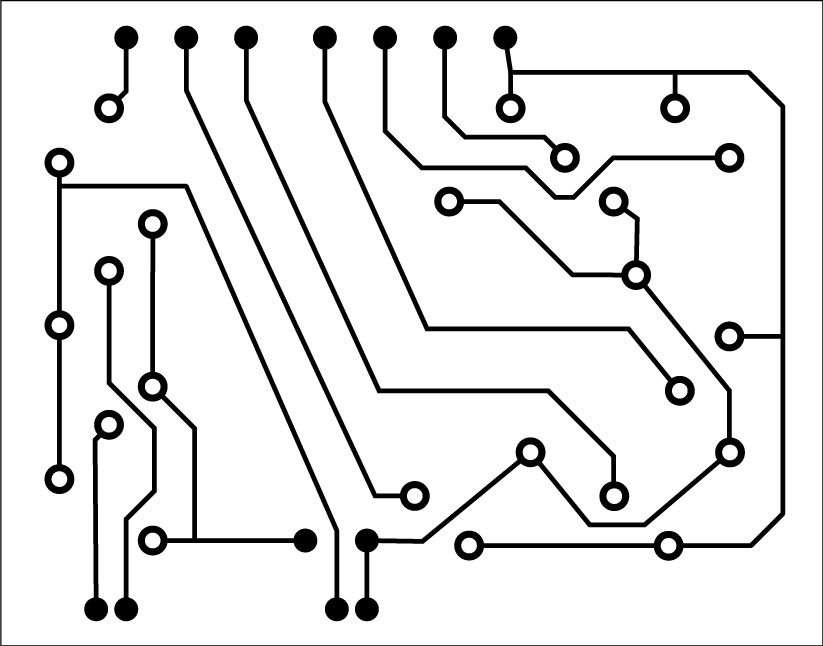

PCB traces PNG (left) and calculating process in Mods (right).

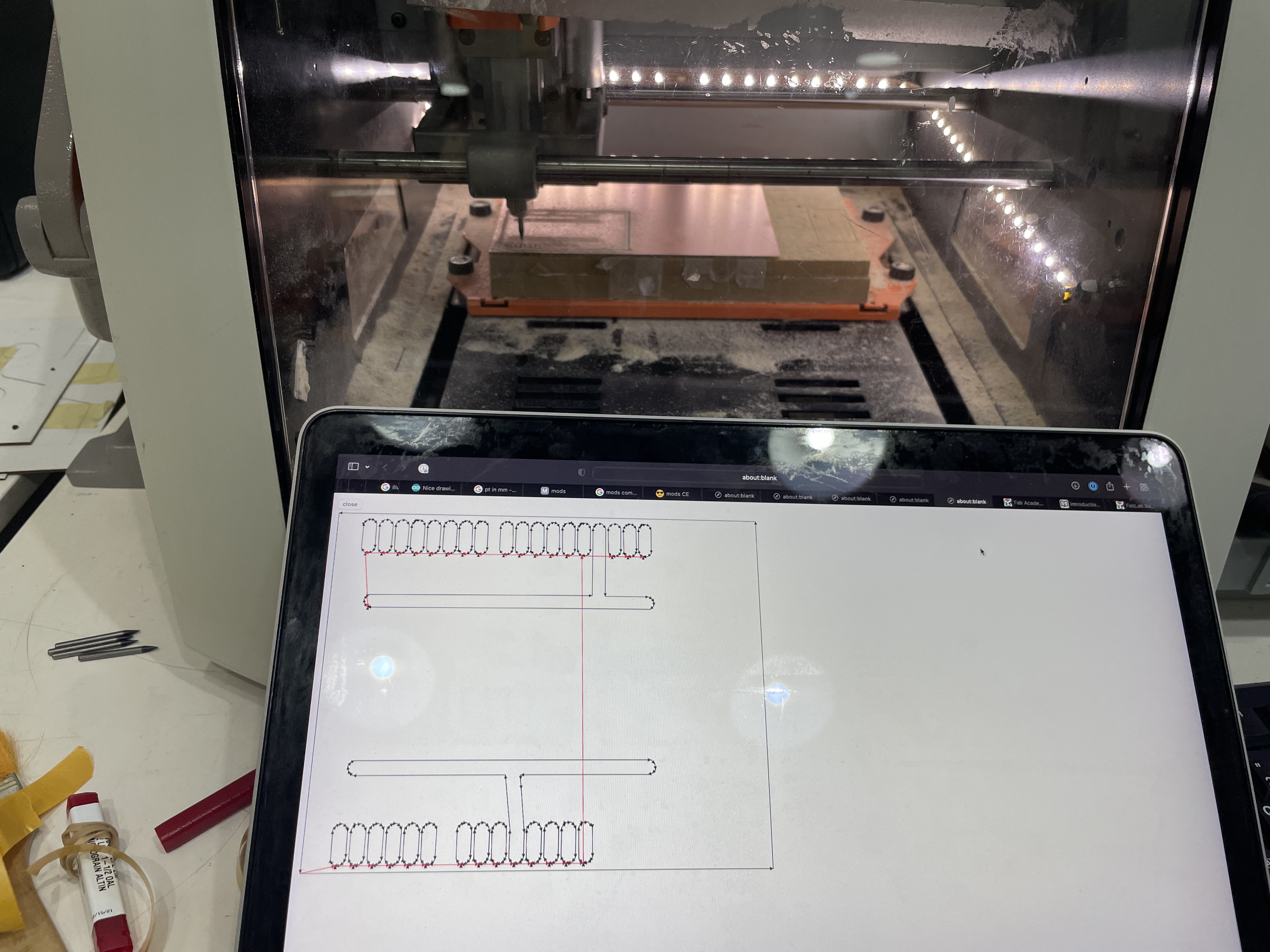

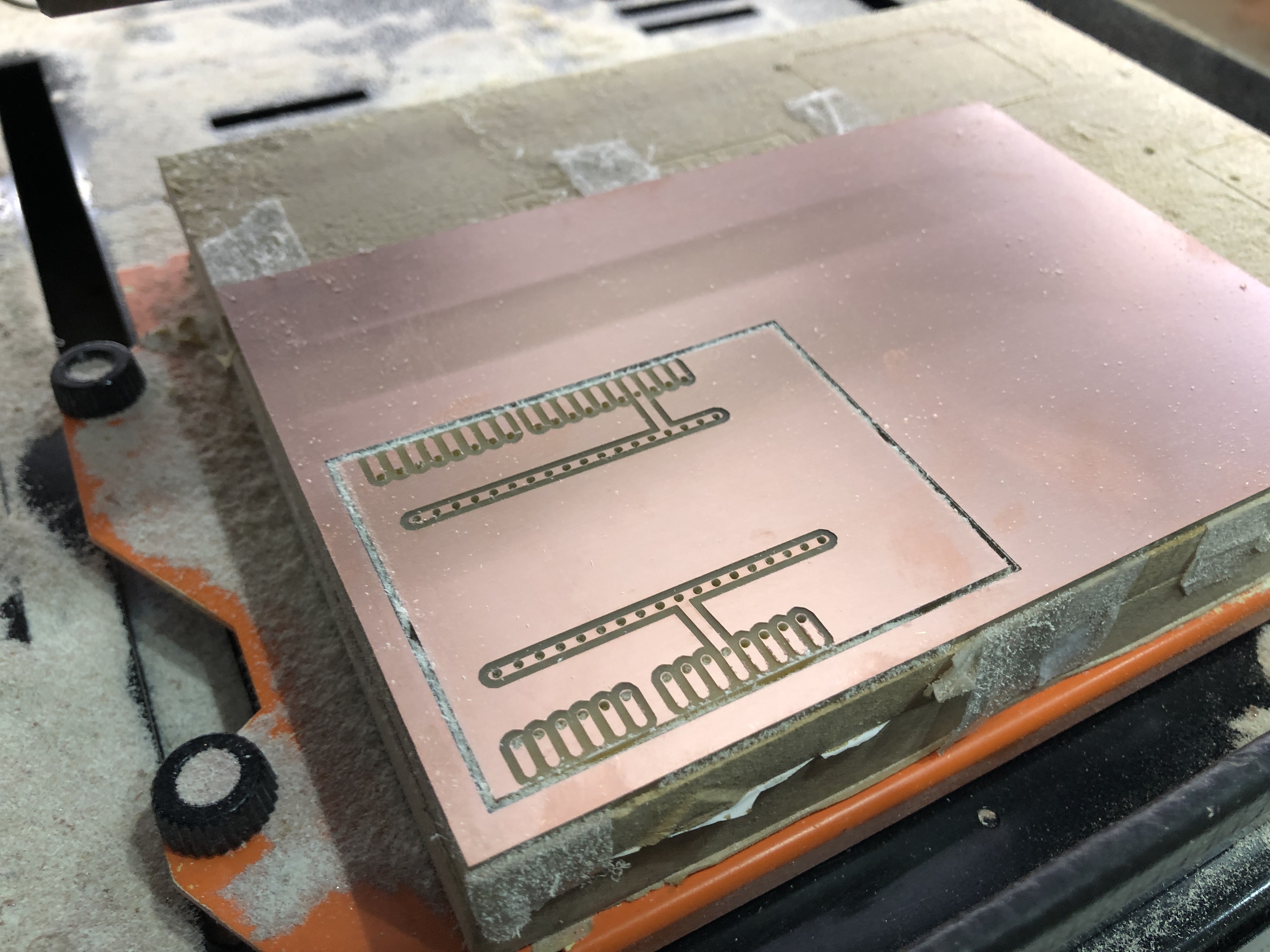

Milling the PCB

Gladly, I managed to avoid all of these pitfalls and quickly managed to finish the design in a short time frame. After exporting the files as PNGs (important: in exactly the same pixel aspect ratio!), I used the Community Edition of MIT's ModsProject to calculate the mill traces from the PNG source and convert them into the proprietary format of the Roland SRM-20 mill. The parameters used in the design and milling process were:

Trace mill: min. 1/64"

Outline mill: 1/32"

Minimal trace width: 0.35mm

Trace clearance: 0.4mm

Hole diameter: 1mm

Find the PCM milling files here

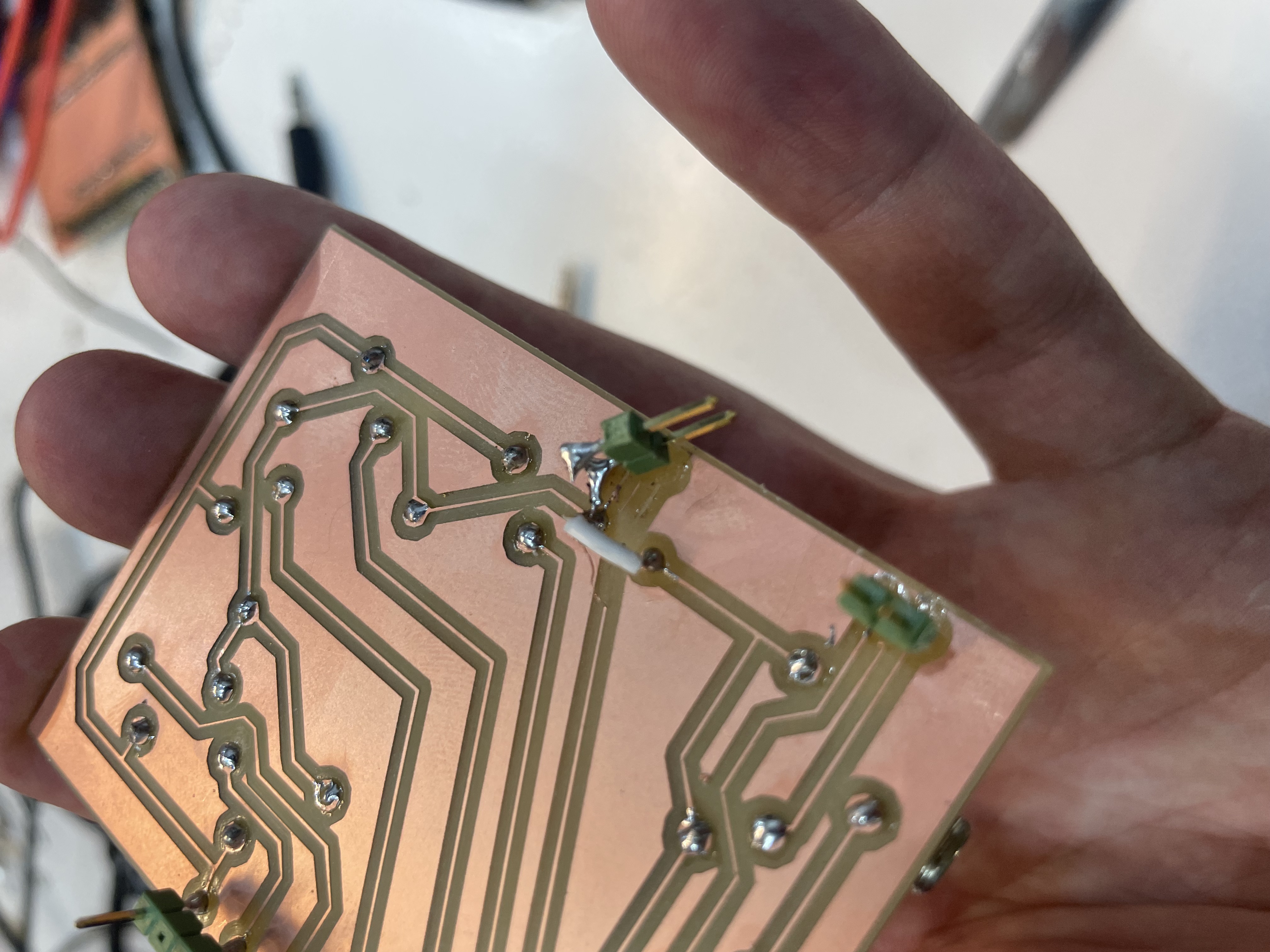

Milling during process (left) and the final milled outcome (right).

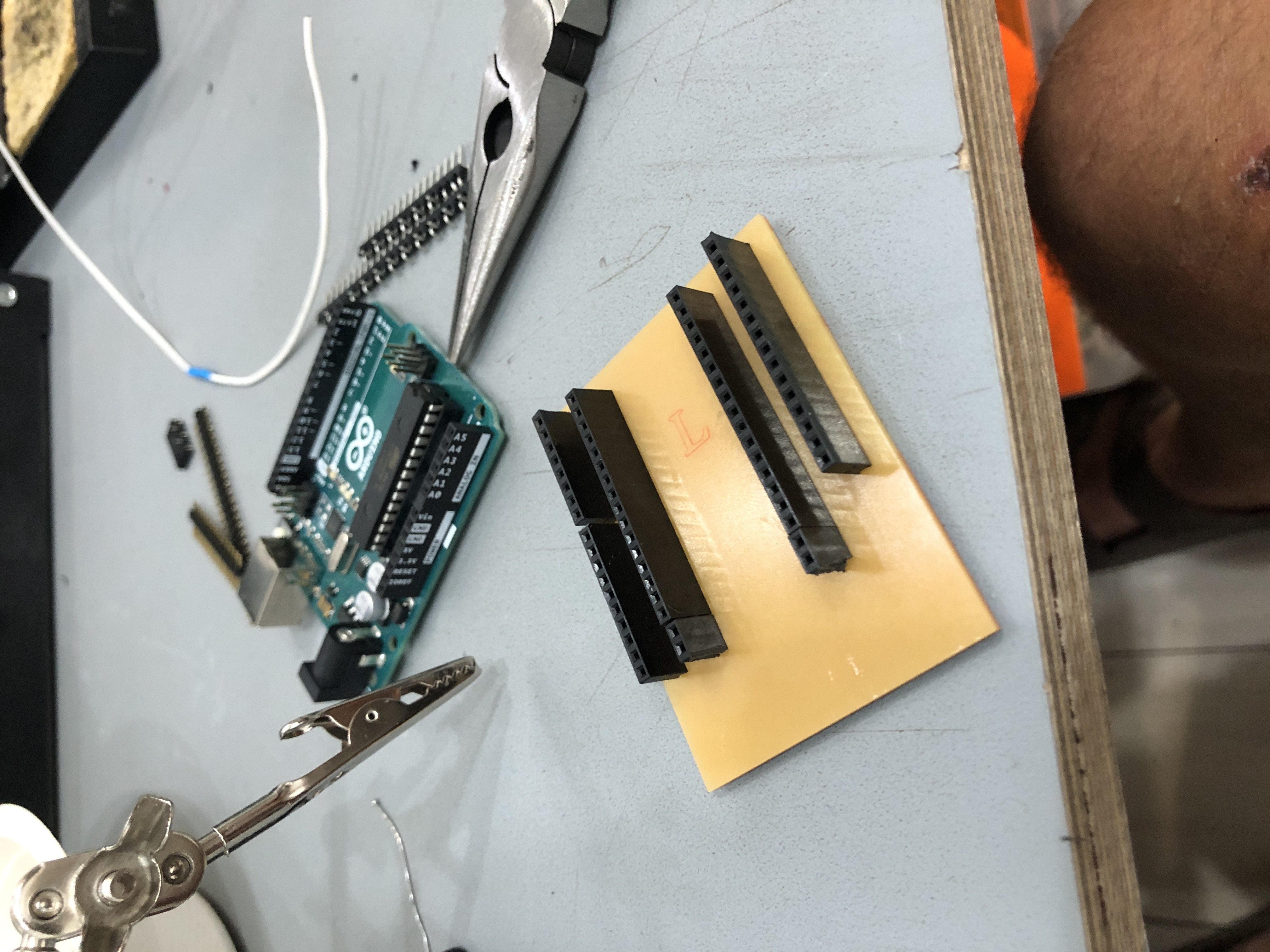

Soldering the PCB

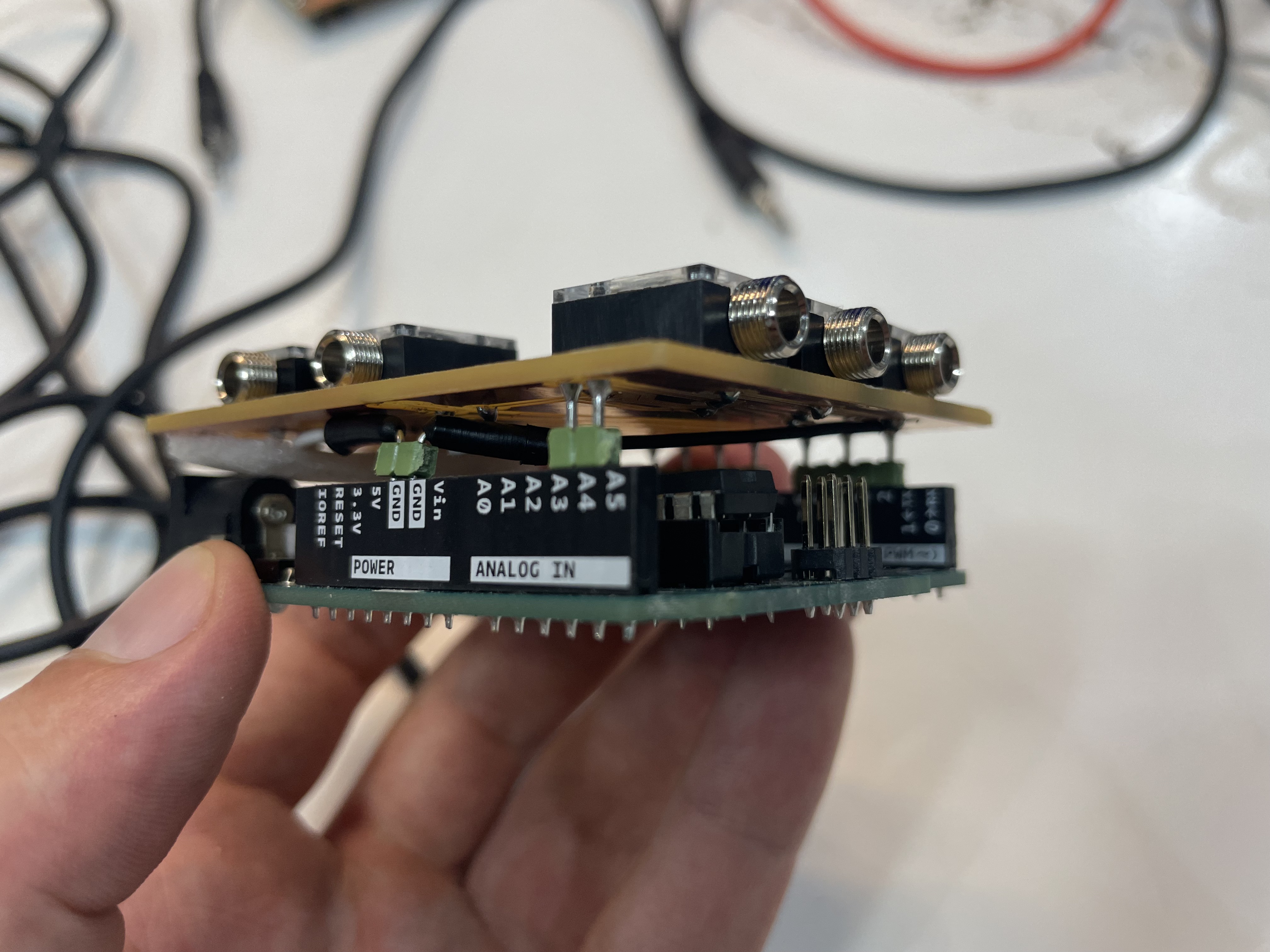

Soldering the PCB was an interesting process due to the fact that the board had been intentionally designed in an inverted fashion: Through-holes were milled to receive female header pins to be soldered on the milled side directly on the contact points. This way, the visible side of the PCB is actually the 'back' of the board, showing only the substrate. The lower side (the milled side of the board), featured contact points for male header pins to be soldered directly on top without any through-holes. This way, the whole design was able to be executed with a single-side PCB, even though it features more than 100 headers (102 to be precise) on two sides of the board. Consequently, the soldering took almost two hours to complete. The outcome is nothing spectacular pr fancy, but the certainly our group is proud of.

Soldering during process (left) and the final soldered outcome, showcasing the male headers plugging into the Arduino (right).

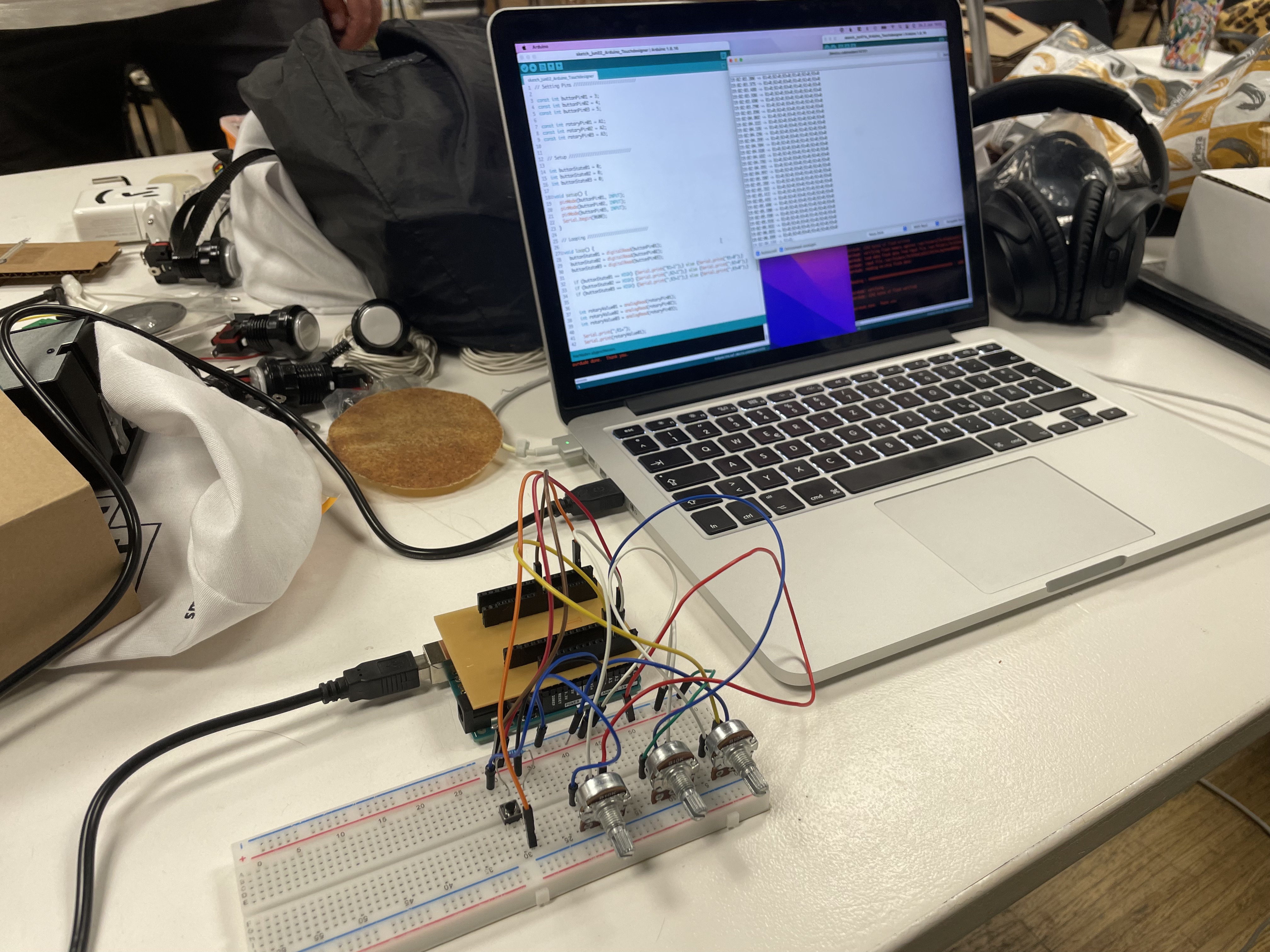

Using the PCB

As simple the PCB is in its design, as effective it is in its use. Over the last two days, we managed to reduce the amount of circuitry on the breadboard almost completely and move everything to our Arduino shield. As mentioned above, this is not the most sophisticated design, but its incredibly effective and we were able to manufacture it in less than five hours – including design, milling and soldering.

The next evolutionary step is to redesign the board in order to offer integrated circuits for the potentiometers and buttons (including pull-up resistors) and offering each one of those as a JST or Grove connector style plug. This would effectively be comparable to a custom and enhanced Arduino Grove shield and offer a comparable plug-and-play functionality. For this step to be reached we need to settle on the exact number of connected potentiometers, buttons, pressure sensors and capacitive touch sensors. When or if we get to that point, this post will be updated.

Beginning to use the shield in order to phase out the breadboard circuitry.

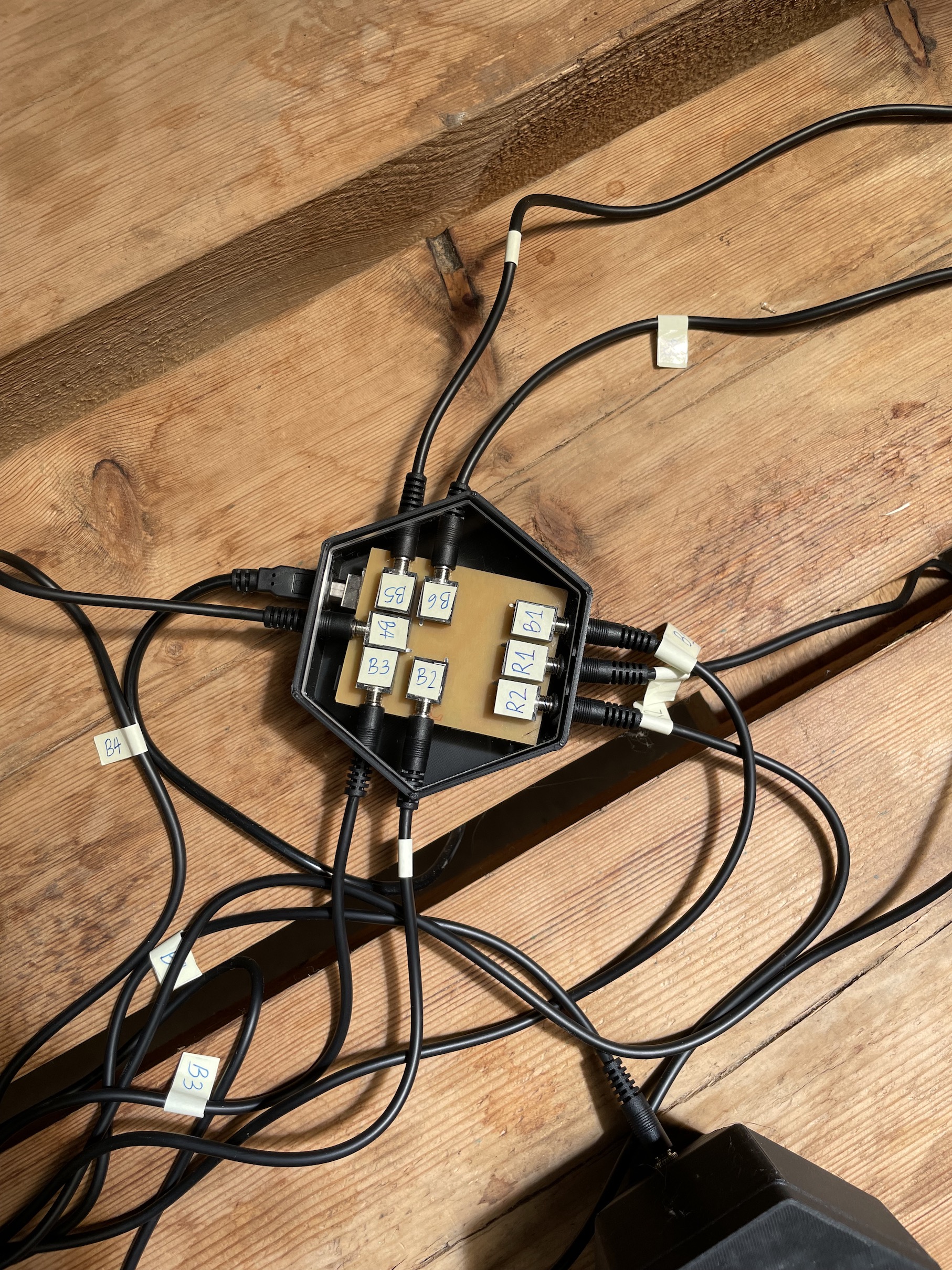

Fabricating a Second Arduino Shield

In order to iterate in the proof of concept shown above, we tackled the challenge to introduce a new connector standard between our Arduino shield and the eight control units. After evaluating different solutions, among them MOLEX and Grove connectors, and weighing them agains their availability, price and open-source qualities, we settled on 3-pole 3,5mm standard headphone jacks. This allowed us to quickly purchase the needed quantity of components needed for the PCB fabrication, the controllers and long connecting wires. The drawback was that the sequential nature of the connector presents a constant risk of shorts. This is why the leading credo with this solution was: Never hot plug!

To integrate the connector standard into our project, we redesigned the Arduino shield used in Fab Challenge IV. After using the wrong pins on the eight surface mounted female 3,5mm headphone jacks, we redesigned the PCB a third time to allocate the correct connections. More impressions below.

Second PCB design including eight surface mounted female 3,5mm headphone jacks – unfortunately using the wrong pins...

Correcting the previous mistakes, using the right pins on the headphone jacks SMDs, shown here as black and white traces ready to be milled. Notice the minimal 0,4mm trace width.

Left: Due to the minimal trace width, we pulled off the copper traces off the substrate after soldering two male pins onto it. Right: Mitigating the problem via two cut jumper wires, which short the necessary traces at another point of the PCB.

Left: The final PCB after soldering the headphone jacks. Right: The central unit in its final 3D printed case including an acrylic cover.

Further Links

Output Devices

electrical safety

~1 mA: OK

~10 mA: shock, contraction

~100 mA: fibrillation

body: M ohm external, k ohm internal

dielectric breakdown: ~kV/mm

supply capacitors

inductive flyback

protection diodes

connector polarization, orientation

protection

power

USB

supplies

switching, linear, regulated

supercapacitor

batteries

LiPo

charge controller

storage

wireless

current measurement

supply regulation

sense resistor

magnetic field

inductance

RGB LED

current limiting

PWM

hello.RGB.45

board

components

traces

interior

C

makefile

video

pinouts

pixels

lights

wires

LEDs

diode drop, series-parallel

MOSFET

N, P

floating gates

gate resistors

BJT, BiCMOS, IGBT

hello.LEDs.t412

board

components

traces

interior

hello.LEDs.t412.ino

video

thermal runaway

eye safety

LED

array

Charlieplexing

hello.array.44

board

components

traces

interior

C

makefile

video

hello.array.44.2

board

components

bottom

vias

top

interior

C

makefile

video

displays

LCD

HD44780

library

hello.LCD.44

board

components

traces

interior

C

makefile

video

I2C

PCF8574

library

hello.I2C.t1614

hello.LCD.I2C.ino

video

OLED

SSD1306

library

library

scripts pinout

hello.SSD1306.45

board

components

traces

interior

C

makefile

video

TFT

ILI9341

library

hello.ILI9341.SW.D21E

board

components

traces

interior

video

hello.ILI9341.HW.D21E

board

components

top

bottom

holes

interior

video

ST7735

video

E Ink

modules

video

RS170, NTSC, PAL, SECAM, VGA

75 ohm impedance

hello.video.44

board

components

traces

interior

C

makefile

video

SPI

TVout

thinner client

color

speaker

DAC, PWM

hello.speaker.45

board

components

traces

interior

C

makefile

video

wavetable

audio

synthesis

low-pass filter

class D amplifier

solenoid

DC motor

H-bridge

A4950

TB67H451FNG,EL

hello.H-bridge.44

board

components

traces

interior

C

makefile

video

Dual H-bridge

DRV8847

torque, power, efficiency, gearing

vibration

servo motor

50 Hz ~1-2 ms PWM

(dis)continuous rotation

ATtiny412

hello.servo.t412

board

components

traces

interior

hello.servo.t412.ino

hello.servo-registers.t412.ino

video

ATSAMD11C

hello.servo-D11C

board

traces

interior

Gerber

top copper

solder mask

silkscreen

outline

ATtiny44

hello.servo.44

board

components

traces

interior

ZLDO1117

hello.servo.44.1

board

components

traces

interior

LM2940

C (hardware PWM)

makefile

C (two-channel, software PWM)

makefile

video

brushless DC motor (BLDC)

efficiency, density, reliability, noise

inrunner, outrunner, pancake, fan

Kv (RPM/V)

~1,10,100,1000 A,$

triple half-bridge

DRV11873

drive waveform

open-loop, closed-loop control

back EMF (BEMF) sensing

electronic speed controller (ESC)

hello.ESC.44

board

components

traces

interior

C

makefile

video

firmware

servo PWM

initialization, calibration

stepper motor

types

wire identification

step PWM, duration

microstepping

step and direction

DRV8428

hello.DRV8428

board

components

traces

interior

hello.DRV8428.ino

video

hello.DRV8428-D11C-NEMA17

board

components

traces

holes

interior

Gerber

top copper

solder mask

silkscreen

outline

hello.DRV8428-D11C

board

components

traces

holes

interior

hello.DRV8428-D11C.ino

video

DVR8428P

DRV8436

bipolar H-bridge

hello.stepper.bipolar.44

board

components

traces

interior

full

makefile

video

unipolar NMOSFET

hello.stepper.44

board

components

traces

interior

wave

makefile

full

makefile

half

makefile

video

electro-permanent

motor control

Allegro

TI

Trinamic

Pololu

TinyG

RAMPS

Mechaduino

nRF52

DDMC

solid state relay

AC vs DC

IC

hockey puck

wiring

voltage drop: ~V

safety: switch hot side

US: black (red,blue) = hot, white = neutral, green(-yellow) = ground

EU: brown (black,gray) = hot, blue = neutral, green-yellow = ground

switched outlet

shape memory

piezo

polymer

artificial muscle

fishing line

conducting thread

actuator

soft

inflatable

pneumatics

hydraulics

assignment

individual assignment:

add an output device to a microcontroller board you've designed,

and program it to do something

group assignment:

measure the power consumption of an output device

Input Devices

inputs

ports

comparator

A/D

I2C

switch

button

slide

hello.button.45

board

components

traces

interior

hello.button.45.c

makefile

video

hello.button.t412

board

components

traces

interior

hello.button.serial.ino

hello.button.t412.ino

hello.button.D11C

board

components

traces

interior

hello.button.USB.ino

hello.button.D11C.ino

debouncing

magnetic field

Hall effect

hello.mag.45

board

components

traces

interior

hello.mag.45.c

makefile

hello.mag.45.py

video

hello.mag.45.html

hello.mag.45.js

video

mods

hello.mag.t412

board

components

traces

interior

hello.mag.serial.ino

hello.mag.t412.ino

hello.mag.D11C

board

components

traces

interior

hello.mag.USB.ino

hello.mag.D11C.ino

vector

applications

simulation

hello.TLE493D.t412

board

components

traces

interior

hello.TLE493D.t412.ino

.c

.make

.py

video

potentiometer

hello.DRV8428-D11C-NEMA17

step response

resistance, capacitance, inductance, position, pressure, tilt,

acceleration, humidity, proximity, touch, multitouch, force, bending, ...

transmit-receive

hello.txrx.t1624

board

components

traces

interior

hello.txrx.t1624.ino

hello.txrx.t1624.py

video

hello.txrx.45

board

components

traces

interior

hello.txrx.45.c

makefile

hello.txrx.45.py

video

loading

hello.load.45

board

components

traces

interior

hello.load.45.c

makefile

hello.load.45.py

video

dielectric spectroscopy

application

theory

measurement

VNA

temperature

bridges

NTC

RTD thermistors

hello.temp.45

board

components

traces

interior

hello.temp.45.c

makefile

hello.temp.45.py

video

IR

thermocouples

light

LED reverse bias current

IR

visible phototransistor

hello.light.45

board

components

traces

interior

hello.light.45.c

makefile

hello.light.45.py

video

synchronous detection

spread spectrum

hello.reflect.45

board

components

traces

interior

hello.reflect.45.c

makefile

hello.reflect.45.py

video

color

RGB

hello.VEML6040.t412

board

components

traces

interior

hello.VEML6040.ino

hello.VEML6040.py

video

motion

Doppler radar

hello.RCWL-0516

board

components

traces

interior

hello.RCWL-0516.c

makefile

hello.RCWL-0516.py

video

pyroelectric

hello.HC-SR501

board

components

traces

interior

hello.HC-SR501.c

makefile

hello.HC-SR501.py

video

distance

optical

module

library

hello.VL53L1X.t1614

board

components

traces

interior

hello.VL53L1X.ino

hello.VL53L1X.py

video

sonar

hello.HC-SR04

board

components

traces

interior

hello.HC-SR04.c

makefile

hello.HC-SR04.py

video

LIDAR

location, time

GNSS

NMEA

NEO-6

GT-U7

module

hello.GPS.t1614

board

components

traces

interior

hello.GPS.t1614.ino

video

acceleration, orientation, rotation

3 axis accelerometer

hello.ADXL343

board

components

traces

interior

reflow

hello.ADXL343.c

makefile

calibration

hello.ADXL343.py

video

6 axis accelerometer+gyroscope

module

library

hello.LSM6DS33.t1614

board

components

traces

interior

hello.LSM6DS33.ino

hello.LSM6DS33.py

video

9 axis accelerometer+gyroscope+magnetometer

module

AHRS library

hello.MinIMU9v5.t1614

board

components

traces

interior

hello.MinIMU9v5.ino

hello.MinIMU9v5.py

video

module

AHRS library

sound

MEMS

digital

I2S

library

hello.CMM-4030D-261-I2S-TR.t1614

board

components

traces

interior

hello.CMM-4030D-261-I2S-TR.ino

hello.CMM-4030D-261-I2S-TR.py

video

analog

hello.SPU0414HR5H

board

components

traces

interior

hello.SPU0414HR5H.c

makefile

hello.SPU0414HR5H.py

video

electret

op-amp

hello.mic.45

board

components

traces

interior

hello.mic.45.c

makefile

hello.mic.45.py

video

speech

vibration

piezo

force

force sensing resistor

strain gauge

load cell

capacitance

angle

pressure

pulse

air pollution

gases

image

modules

ESP32-CAM

hello.ESP32-CAM

board

components

traces

holes

interior

camera

library

video

hello.ESP32-CAM.ino

video

webcams

boards

libraries

OpenCV

OpenCV.js

SimpleCV

libuvc

guvcview

WebRTC

video.html

video

browser security

assignment

individual assignment:

measure something: add a sensor to a microcontroller board

that you have designed and read it

group assignment:

probe an input device's analog levels and digital signals